Revolutionizing Quality Control with Advanced Hazelnuts Sorting Machines

Advanced nut sorting machine technology combines H...

More

Food recalls from foreign objects highlight the necessity of advanced detection. Recent incidents have included:

Plastic material in salad dressings.

Metal fragments in popular sodas.

Leading brands—Mettler-Toledo, Loma Systems, Nordson, Anritsu, and Thermo Fisher—provide powerful x ray food inspection systems. A successful selection matches a system’s detection accuracy and speed to production needs.

Selecting the right brand involves a deep dive into each company's technological strengths, target applications, and operational philosophy. The top five manufacturers each offer unique advantages for specific production environments.

Mettler-Toledo stands out for its focus on integrated, high-sensitivity inspection solutions. The company designs systems that combine multiple quality control functions into a single, efficient footprint. This approach provides significant benefits for modern food producers.

Key technological innovations define their latest systems:

The X2 Series integrates directly into C-Series checkweighers, boosting detection sensitivity.

This combination creates a space-saving design by sharing components like conveyors.

Producers benefit from a reduced total cost of ownership, as a single vendor handles documentation, installation, training, and service.

Optional vision inspection technology creates 3-in-1 or 4-in-1 systems that also check for packaging defects and verify label data.

Industry 4.0 ReadyMettler-Toledo systems are built for the modern factory. They connect to ProdX software, enabling real-time monitoring, simplified food safety compliance, and enhanced productivity through data-driven insights.

The company tailors its x ray food inspection systems to specific industry needs. The X6 Series targets manufacturers of medium to large packaged products seeking to upgrade their inspection processes. In contrast, the X3 Series of bulk flow systems primarily serves agriculture, confectionery, and dried food producers. Common applications for the X3 include inspecting nuts, cereals, pulses, and frozen vegetables.

Loma Systems engineers its equipment for maximum throughput and reliability, making it a top choice for high-volume production lines. Their machines are built to withstand the demands of continuous, 24/7 operation without sacrificing accuracy.

Loma's systems excel in high-speed environments through several core features:

Exceptional Throughput: They can inspect over 600 packs per minute, or at line speeds of 90m/min (300 ft/min).

Dynamic Analysis: This technology maximizes detection performance while significantly reducing false rejects.

Product Learn Wizard: This feature enables fast setup and product switching. It automatically optimizes the system for a new product type within minutes.

AAT Technology: Adaptive Array Technology (AAT) allows operators to change X-ray diode settings based on the product. This provides optimal detection levels for different contaminants without stopping the line.

These systems also handle product density variations with ease, allowing them to inspect randomly oriented products on a production run without issue. Heavy-duty conveyor components ensure long-term reliability, making Loma a dependable partner for demanding schedules.

Nordson differentiates itself with a strong emphasis on user-friendly software and robust process control. The company provides intuitive platforms that empower quality control teams to manage data effectively and minimize operator error.

Nordson's software enhances usability and data management through a powerful Human Machine Interface (HMI). This touchscreen control simplifies programming and displays process information clearly, reducing setup time. Several features improve quality control:

Automated Pressure Regulation: An operator lockout function prevents unauthorized manual changes to dispense parameters, eliminating inconsistencies.

Barcode Scanning: Operators can switch between stored dispensing programs by scanning a barcode, which also enables lot code scanning for complete part traceability.

Memory Programs: The system stores up to 16 sets of dispensing parameters, which operators can recall at any time to eliminate manual data entry.

Digital Dispense Log: It automatically records critical data for each cycle, storing up to 10,000 lines of information. This supports stringent, documented process control for regulatory compliance.

These software tools, combined with high-resolution Automated Optical Inspection (AOI), give production managers powerful analysis capabilities for superior defect detection.

Anritsu is recognized for designing highly efficient and low-maintenance systems that reduce lifetime operating costs. Their engineering philosophy prioritizes energy savings and reliability, making them an economical choice over the long term.

The XR75 DualX model exemplifies this approach with its Advanced Long Life (A.L.L.) technology. This design uses long-life, low-power components that generate less heat, which completely eliminates the need for an external cooling system. The result is lower power consumption and a more reliable machine.

While Anritsu systems minimize the need for service, routine maintenance is essential for peak performance.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Belt Check | Daily | Inspect for fraying to prevent contamination. |

| Resin Cover Inspection | Regular | Check for cracks to protect the line sensor. |

| System Cleaning | Regular | Prevents bacterial growth and false rejects. |

| Cooling Fan Filter | Periodic | Clean to prevent heat buildup and extend generator life. |

When service is required, the system's design facilitates quick maintenance with diagnostics, plug-and-play boards, and an easy-release conveyor to reduce downtime.

Thermo Fisher Scientific excels in developing solutions for complex inspection challenges, particularly for products with metallic or dense packaging. Their systems combine high power with sophisticated software to ensure comprehensive detection where other methods may fail.

The Xpert Heavy Duty X-ray inspection system is designed for difficult applications. It uses high power (900W) and a large aperture to inspect big cases, boxes, and trays containing dense products. These systems can penetrate metalized film or foil-based packaging to find small contaminants that metal detectors would miss.

Advanced Detection TechniquesThermo Fisher utilizes innovative methods to eliminate blind spots. Some systems project a wide X-ray beam from the bottom up to a non-linear detector, ensuring full coverage even for upright packages like metal cans. For challenging containers like glass jars, they employ dual-beam inspection to achieve a 100% detection probability.

Their product verification software is equally advanced. The cloud-based platform gives researchers access to powerful analysis tools without needing manual software updates. It allows users to compare their results against a common reference set, ensuring global consistency and confirming product integrity with minimal effort.

Evaluating different brands requires a clear understanding of four key performance indicators. These criteria determine how a system will perform on the factory floor and impact the bottom line.

A system's effectiveness hinges on its ability to distinguish contaminants from the product. X-ray inspection works by detecting differences in density.

Higher density products or contaminants appear darker on scans because they absorb more X-ray energy.

Detection becomes challenging if a contaminant and the food product have similar densities.

Product characteristics like moisture content and temperature can alter density, affecting detection accuracy.

Advanced algorithms analyze these density variations in real-time to flag irregularities.

Modern x ray food inspection systems are designed for seamless integration. Manufacturers offer solutions that connect with existing equipment, including various conveyor types and factory management software. Some providers, like JLS Automation, even assume full system responsibility, handling all controls integration and programming to ensure the new equipment works perfectly within the established production line. This approach minimizes downtime and maintains high throughput speeds.

These systems are crucial for meeting stringent food safety standards like HACCP and GFSI. They provide the necessary documentation and control to pass audits.

Automated record-keeping is a cornerstone of modern compliance. Systems generate digital, time-stamped logs of all inspection activities, creating a verifiable audit trail. This enhances traceability and helps businesses prove due diligence.

Features supporting compliance include hygienic designs that prevent bacterial growth, fail-safe inspection capabilities, and multifunctional quality checks performed simultaneously with contaminant detection.

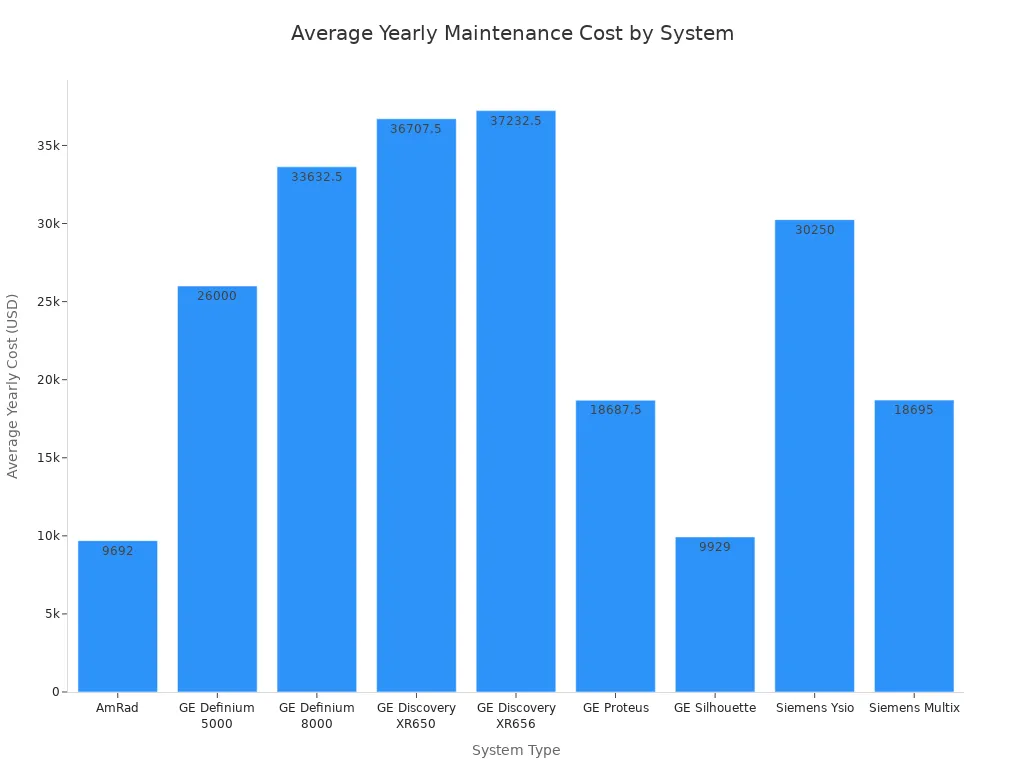

The initial purchase price is only part of the total investment. Ongoing maintenance, spare parts, and software updates contribute significantly to the lifetime cost. Preventive maintenance for imaging equipment typically costs 2-4% of the initial purchase price each year. While the following data is for medical systems, it illustrates the wide range of potential annual service costs.

Official service agreements often cover security patches, but major software upgrades may incur extra charges.

Selecting the right brand depends on aligning its core strengths with your specific operational demands. Whether you prioritize speed, sensitivity, or budget, a tailored solution exists.

For facilities with demanding production schedules, throughput is paramount. Loma Systems excels in this area, engineering machines for maximum speed and reliability in 24/7 environments. Large-scale producers have successfully adopted similar high-throughput technologies. For example, a major German dairy processes over two million liters of milk daily using advanced monitoring. Similarly, Companion Baking Company, a wholesale bread producer, boosted its efficiency by 60% in six months by implementing a digital productivity platform on its high-volume lines. These examples show that robust systems are essential for maintaining output without compromising safety.

Detecting low-density contaminants like plastic in products with high moisture or variable density presents a significant challenge. Dual-energy technology offers a superior solution. Eagle's PXT™ technology and TDI Packsys systems use this method to find foreign materials in difficult products like frozen vegetables. These advanced x ray food inspection systems differentiate contaminants from product variations, reducing false rejects. This technology is especially effective for items where moisture or salinity interferes with standard inspection methods.

Small to mid-sized businesses often require compact and cost-effective solutions. Brands like TDI Packsys and Maha X-Ray Equipment cater to this market. TDI Packsys offers its XE series, which provides advanced capabilities in a small footprint at a competitive price. Maha X-Ray Equipment also provides an affordable option with key benefits:

Compact Design: It fits easily into facilities with limited floor space.

Cost-Effective Performance: The system balances essential functionality with an affordable price point.

Dependable Operation: It delivers reliable performance for budget-conscious manufacturers.

The technology behind food inspection is rapidly evolving. Three key trends are shaping the next generation of systems: artificial intelligence, deeper software integration, and new business models. These advancements promise greater accuracy, efficiency, and accessibility for food producers.

Artificial intelligence is transforming contaminant detection. AI-driven systems, particularly those using deep learning, continuously learn from production data. This allows them to recognize new or unusual contaminants without human programming. Companies are developing these adaptive learning technologies to anticipate defects and adjust to product variations automatically.

This intelligence also significantly reduces false rejection rates. Studies show AI can decrease false positives by over 37%, especially when it visually highlights suspicious regions for operators. This approach improves accuracy and minimizes unnecessary product waste.

Modern systems are moving beyond standalone operation. They now integrate deeply with factory-wide software for powerful data analysis.

ERP Integration: Connecting inspection data to an Enterprise Resource Planning (ERP) system creates a real-time quality control loop. It enables full product traceability, linking inspection images to a product's unique ID for root cause analysis.

Cloud Platforms: Cloud-based software allows for remote monitoring and management. Similar to Picture Archiving and Communication Systems (PACS) in medicine, these platforms provide secure, browser-based access to inspection data, simplifying collaboration and reporting.

The industry is seeing a shift toward subscription-based services, or X-ray-as-a-Service (XaaS). This model lowers the barrier to entry for advanced technology. Instead of a large upfront capital investment, businesses pay a predictable monthly fee. This fee often bundles the equipment with maintenance, software updates, and support. This approach makes state-of-the-art inspection capabilities more accessible to small and mid-sized manufacturers.

Selecting the right brand is critical for operational success. Mettler-Toledo offers robust solutions, while Loma Systems meets high-throughput needs. Businesses must evaluate production requirements against accuracy, speed, and cost. Well-chosen x ray food inspection systems represent a future-proof investment in a brand's safety and reputation.

Yes, X-ray inspection is completely safe. The process uses extremely low radiation levels. It does not affect the food's taste, texture, or nutritional value and is approved globally.

Metal detectors only find metallic contaminants. X-ray systems detect metal plus other foreign materials like glass, stone, and dense plastics by identifying differences in product density.

The primary challenge is integrating the new equipment into an existing production line. Proper planning with the vendor minimizes downtime and ensures a smooth, efficient installation process.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Chili, walnut, peanuts, soybeans, c...

Automatic recognition and rejection, fish bone ins...

Recommedation: Rice, wheat, corn, grain, pulses, s...

Recommedation: Small particle, flat products such...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Advanced nut sorting machine technology combines H...

MoreFood safety and quality control demands have evolv...

MoreAs pet owners increasingly view their companions a...

MoreThis article delves into the persistent pain point...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThe X-ray inspection system has revolutionized our quality control process. Detection accuracy for contaminants in packaged meals is exceptional, and the false reject rate is minimal. Highly recommended for food manufacturing.

Sarah Chen

Production SupervisorOutstanding system for our frozen vegetable line. The sensitivity settings are precise enough to detect small bone fragments and stone contaminants without compromising throughput. The user interface is very intuitive for operators.

David Thompson

Plant ManagerReliable performance in detecting metal, glass and plastic contaminants in our bakery products. System integration was smooth and maintenance requirements are low. The only minor issue was initial calibration, but technical support was excellent.

Jennifer Williams

Food Safety DirectorThis X-ray inspection system has been crucial for maintaining our HACCP compliance. The ability to simultaneously check for contaminants while verifying fill levels and package integrity has significantly improved our overall quality assurance.