Safe Paws, Happy Hearts: Mastering Pet Food Safety with Advanced X-Ray Inspection

As pet owners increasingly view their companions a...

More

Foreign materials, like metal and plastic, triggered 12 food recalls in 2024. This underscores a significant risk to public health and brand integrity. An effective automatic food x ray inspection system is a critical defense. The market's projected 7.8% CAGR reflects this growing need. Decision factors include detection accuracy and operational efficiency.

Selecting the right system requires a balanced evaluation of several core operational and financial factors. A thorough analysis of these criteria ensures the chosen equipment meets both safety standards and production demands.

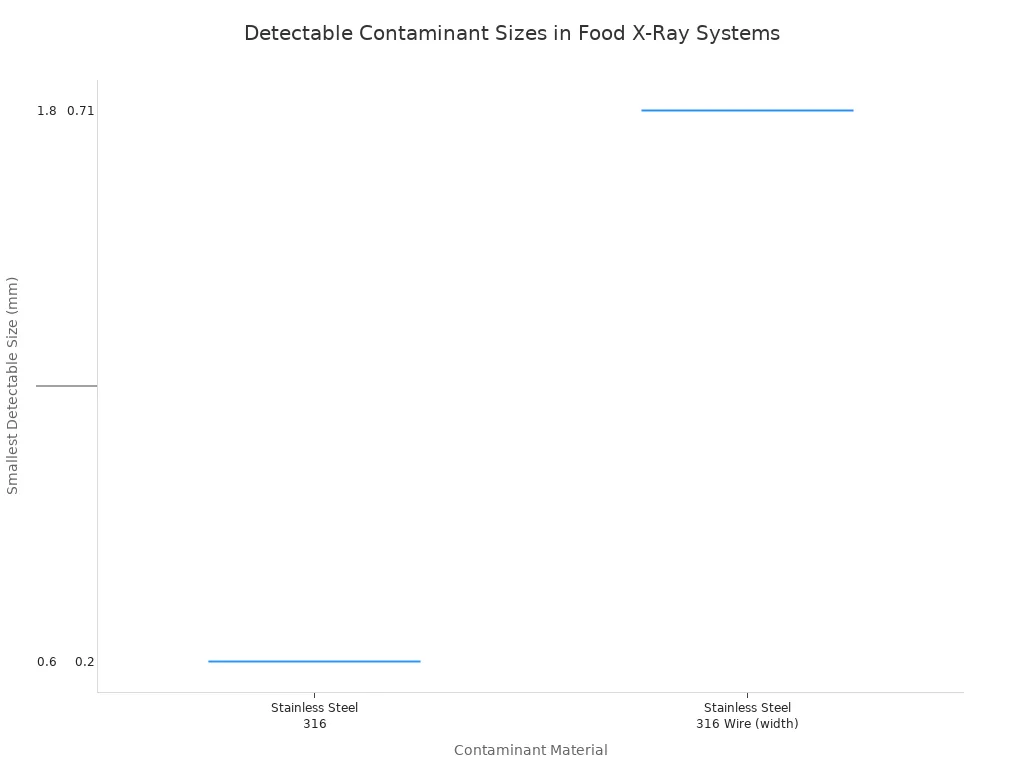

A system's primary function is to detect contaminants with high precision. Modern systems should identify foreign materials as small as 0.3 mm to meet food safety regulations. Detection capability varies by contaminant density and material.

| Material | Smallest Detectable Size (mm) |

|---|---|

| Stainless Steel 316 | 0.6 – 1.8 |

| Soda Lime Glass | 2 – 7 |

| Ceramic | 1.5 – 4 |

| Aluminum | 1.5 – 4 |

Advanced technologies like Dual Energy sensors enhance the detection of low-density contaminants, such as bone or rubber, by analyzing materials at two different energy levels. This improves image resolution and reduces false rejections.

The inspection system must match or exceed the production line's speed to avoid bottlenecks. Modern systems operate at high speeds, inspecting up to 400 packs per minute. Seamless integration with factory management software is also crucial. Many systems use standard SQL interfaces to centralize data for process monitoring and reporting.

An intuitive user interface reduces operator error and minimizes training time. While some providers offer comprehensive 5-day training packages for new operators, a system with simple controls and auto-learn functions streamlines daily operation and product changeovers.

TCO extends beyond the initial purchase price. A complete financial assessment of an automatic food x ray inspection system includes multiple factors.

Key TCO Components:

Initial hardware and software costs

Annual running costs (power, compressed air)

Service, spare parts, and maintenance expenses

Potential downtime and associated production loss

Evaluating these elements provides a true picture of the long-term investment.

Each leading brand offers unique strengths in the food safety market. Understanding their core technologies and target applications helps narrow down the best fit for a specific production line. These companies provide a range of solutions, from entry-level compliance to advanced inspection for complex products.

Mettler-Toledo provides a comprehensive portfolio of x-ray systems known for precision. The company designs its equipment for various applications, particularly bulk foods like nuts, cereals, and vegetables. Their product lines address different operational needs, from general inspection to advanced contaminant detection.

| Product Line | Key Features & Target Applications |

|---|---|

| X3 Series | Inspects bulk products on conveyors and detects contaminants as small as 0.3 mm. |

| X13 System | Offers a cost-effective entry point with advanced detector technology for bulk flow. |

| X53 System | Uses Dual Energy technology to find low-density contaminants in complex products. |

Loma Systems builds robust machines for demanding, high-throughput environments. The company emphasizes durability and efficiency, making its systems a popular choice for busy production facilities.

Loma recently launched its X5DE Dual Energy X-ray Inspection System in North America. This flagship model sets a new standard for contaminant detection in challenging food production settings.

Anritsu specializes in advanced detection technology. Its systems excel at identifying contaminants in difficult or complex product applications. The company is a strong contender for manufacturers dealing with challenging materials or inspection conditions.

Thermo Fisher Scientific focuses on integrated and user-friendly solutions. Their systems are designed for easy operation and seamless integration into existing quality control workflows, helping to streamline processes and reduce operator error.

Eagle PI is a leader in technological innovation for an automatic food x ray inspection system. The company develops advanced features like Material Discrimination X-ray (MDX) to identify inorganic contaminants by composition. It also offers Performance X-ray Technology (PXT) for superior bone detection.

A detailed comparison reveals how each leading brand tailors its technology to specific industry needs. From precision compliance to high-speed durability, understanding these differences is key to selecting the right system for your production line.

Mettler-Toledo establishes its leadership through systems that deliver exceptional detection accuracy and help manufacturers meet stringent global standards. The company engineers its equipment for superior performance, especially in challenging applications involving low-density contaminants.

For detecting items like bone or glass in complex products, Mettler-Toledo offers advanced solutions:

The X53 system integrates HiGain+ Dual Energy (DE) detector technology. It processes two energy spectrums at once, allowing it to differentiate between materials with similar densities, such as stone in a batch of dense nuts. This makes it highly effective at finding low-density contaminants that single-energy systems often miss.

The X13 system provides a cost-effective entry point using HiGain+ detector technology and ContamPlus software. It delivers sharp imaging for reliable contaminant detection in standard bulk applications.

Compliance Confidence 🛡️ Mettler-Toledo systems are designed to help food manufacturers achieve and maintain compliance with key global food safety standards. These include BRCGS, IFS, ISO 22000, FSSC 22000, and HACCP principles.

Loma Systems builds robust machines designed to withstand the rigors of demanding, 24/7 production environments. The company prioritizes durability and operational efficiency, making its systems a trusted choice for high-volume industries like meat, poultry, and ready meals. Case studies with companies like Bertolino Foods and De Keyser demonstrate the equipment's reliability in scaling up processing operations.

Loma designs its systems for harsh conditions. The flagship X5DE X-ray Inspection System has an IP66 rating, protecting it from dust and powerful water jets. For the most intensive washdown protocols, Loma offers IP69-rated equipment in its metal detector and checkweigher lines, ensuring resilience in wet and dusty settings.

To maximize uptime, Loma's IQ series of detectors features an enhanced auto-learn function. This system automatically selects the optimal operating frequency for different products, which significantly reduces setup time and minimizes costly downtime during product changeovers.

Anritsu excels in developing technology for difficult inspection scenarios, such as products with variable shapes and densities. Its dual-energy X-ray systems provide superior detection where conventional technology may struggle.

Anritsu's technology works by acquiring two images simultaneously using high and low X-ray energies. The system analyzes how different materials absorb these energies and effectively subtracts the product's image from the background. This process isolates contaminants, making them clearly visible even in complex products like bags of salad or overlapping items. The new DualX HR sensor further enhances this capability, producing sharper images and improving sensitivity for fine metals and small bones without being affected by product shape.

Thermo Fisher Scientific focuses on creating a seamless user experience. The company designs its systems for easy integration and straightforward operation, helping to streamline quality control workflows and reduce the potential for operator error. This makes an automatic food x ray inspection system from Thermo Fisher an excellent choice for facilities looking to transition from metal detection.

The NextGuard system exemplifies this user-centric approach with features designed for simplicity:

A compact size allows for easy installation on existing lines.

An intuitive user interface minimizes the learning curve for new operators.

A modular design enables rapid diagnosis and repair, maximizing uptime.

Built-in remote monitoring allows for swift troubleshooting by technicians.

For facilities requiring deep integration, Thermo Fisher's SampleManager LIMS software connects seamlessly with analytical instruments. It enables real-time data collection and can even suspend instruments found to be out of control, creating a truly connected and automated quality assurance process.

Eagle PI stands at the forefront of innovation with its advanced detection technologies. The company's systems go beyond simple contaminant detection to perform sophisticated material analysis and simultaneous quality checks.

Eagle’s signature Material Discrimination X-ray (MDX) technology is a game-changer for complex products. It works by measuring the ratio of two different X-ray energies absorbed by a material, allowing it to differentiate items based on their atomic number. This enables the system to detect historically difficult inorganic contaminants.

| Contaminant | Product Example |

|---|---|

| Flat Glass, Stone | Mixed nuts, trail mix, cereals |

| Low-Density Rubber | Bags of potatoes, salads, sweets |

Furthermore, Eagle's SimulTask™ PRO software empowers its systems to perform multiple quality control tasks in a single pass at high speeds. This includes not only detecting foreign bodies but also verifying product mass and counting components in multi-pack items, consolidating quality control into one efficient step.

Selecting the right automatic food x ray inspection system depends on specific production needs. Mettler-Toledo offers precision, Loma ensures durability, Anritsu handles complexity, Thermo Fisher provides usability, and Eagle PI excels in material discrimination.

Use these insights to shortlist vendors. Request targeted demos to validate performance in your facility.

Yes. Food inspection systems use extremely low energy levels. The process does not affect food safety, texture, or nutritional value, ensuring product integrity remains completely intact.

X-ray systems detect a wider range of contaminants, including non-metallic items like glass, stone, and bone. Metal detectors can only identify metallic foreign bodies.

Yes. X-ray technology effectively inspects products through foil and metalized film packaging. This capability provides a significant advantage over many standard metal detection systems.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Conventional and unconventional contaminant detect...

High cost performance, compact design, high sensit...

Recommedation: Small particle, flat products such...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

As pet owners increasingly view their companions a...

MoreIn the fast-paced world of food production, ensuri...

MorePicture a high-speed frozen broccoli line running ...

MoreFor processors, the challenge is evolving. It is n...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThese X-ray machines have revolutionized our food inspection process. The detection accuracy for contaminants is exceptional, and the false rejection rate has dropped significantly. Highly recommended for any serious food production facility.

Sarah Chen

Production SupervisorOutstanding performance in detecting metal fragments and other contaminants in our packaged snacks. The user interface is intuitive, and maintenance requirements are minimal. This investment has greatly enhanced our product safety standards.

David Thompson

Food Safety OfficerReliable and efficient X-ray system that consistently identifies foreign objects in our meat products. The image clarity is impressive, and the automated rejection system works flawlessly. Minor software glitches, but overall excellent value.

Jennifer Williams

Plant ManagerThis X-ray inspection machine has been a game-changer for our bakery operations. It effectively detects glass, metal, and plastic contaminants in our products while maintaining high throughput. The technical support team is responsive and knowledgeable.