How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about cont...

More

An X-ray inspection system is a quality control technology. It uses density differences to find physical contaminants inside food products. This process ensures the safety and integrity of products without harming the food itself. It helps prevent foreign objects like metal, glass, and stone from reaching consumers.

Recent data highlights the importance of this technology. In the United States, foreign object contamination causes 11.4% of all food recalls. Physical contamination events are also a concern elsewhere. Recent recalls involved glass in yogurt, metal in jam, and plastic in cooked chicken. An x ray machine for food industry provides a critical defense.

Food manufacturers implement X-ray inspection for several critical reasons. This technology provides a powerful defense for their products, consumers, and brand reputation. It is a proactive measure in a competitive market.

A single product recall can cause significant damage. For instance, a dairy company once recalled butter from major supermarkets due to possible metal contamination from damaged equipment. Such incidents erode public confidence. A 2022 NielsenIQ survey showed that 68% of consumers would stop buying from a brand after a food safety issue. Protecting consumers is the primary goal. A strong brand reputation is a direct result of that commitment.

Regulatory bodies demand strict safety protocols. In the U.S., the FDA's Food Safety Modernization Act (FSMA) requires facilities to have a written food safety plan. This plan must identify physical hazards and establish preventive controls to minimize them.

An x ray machine for food industry helps companies comply with these mandates. It also supports adherence to Global Food Safety Initiative (GFSI) standards, which are often required by major retailers. Meeting these benchmarks is essential for market access.

X-ray systems offer capabilities beyond traditional metal detectors. They identify a wide array of foreign objects based on density differences. This includes non-metallic contaminants that can accidentally enter the production line.

Dense plastics

Rubber and Teflon

Glass shards

Calcified bone

Additionally, this technology performs important quality control checks. It can verify correct fill levels in containers, confirm all components are present in a package, and even spot broken or missing items, ensuring the final product is perfect.

An x ray machine for food industry operates on a simple yet powerful principle. It inspects products by measuring density differences. The process is straightforward and highly effective for quality control on a production line.

An X-ray system has several key components working together. The optimal configuration depends on factors like product type, line speed, and the specific contaminants of concern. The core components include:

An X-ray generator that emits a beam through the food product.

A detector on the opposite side that captures the X-ray energy passing through.

A computer with image processing software that analyzes the resulting image.

As a product travels along a conveyor belt, it passes between the generator and the detector. The detector measures the amount of X-ray energy that reaches it. Dense objects absorb more energy, creating a distinct signature for the system's software to analyze.

The system's software is the brain of the operation. It converts the captured X-ray data into a grayscale image. In this image, denser materials appear darker, while less dense materials appear lighter.

Advanced imaging software uses a wide grayscale range, sometimes from 0 to 65,535. This provides high-resolution images with exceptional detail, making it easier to spot even small contaminants.

A foreign object like a piece of metal or glass will absorb more X-rays than the surrounding food. This creates a darker spot on the grayscale image, which the software flags as a contaminant. To ensure accuracy, operators calibrate the system for specific products by adjusting sensitivity and detection thresholds. Advanced systems even feature adaptive learning. They continuously analyze production data to refine detection criteria, improving accuracy and reducing false alarms over time.

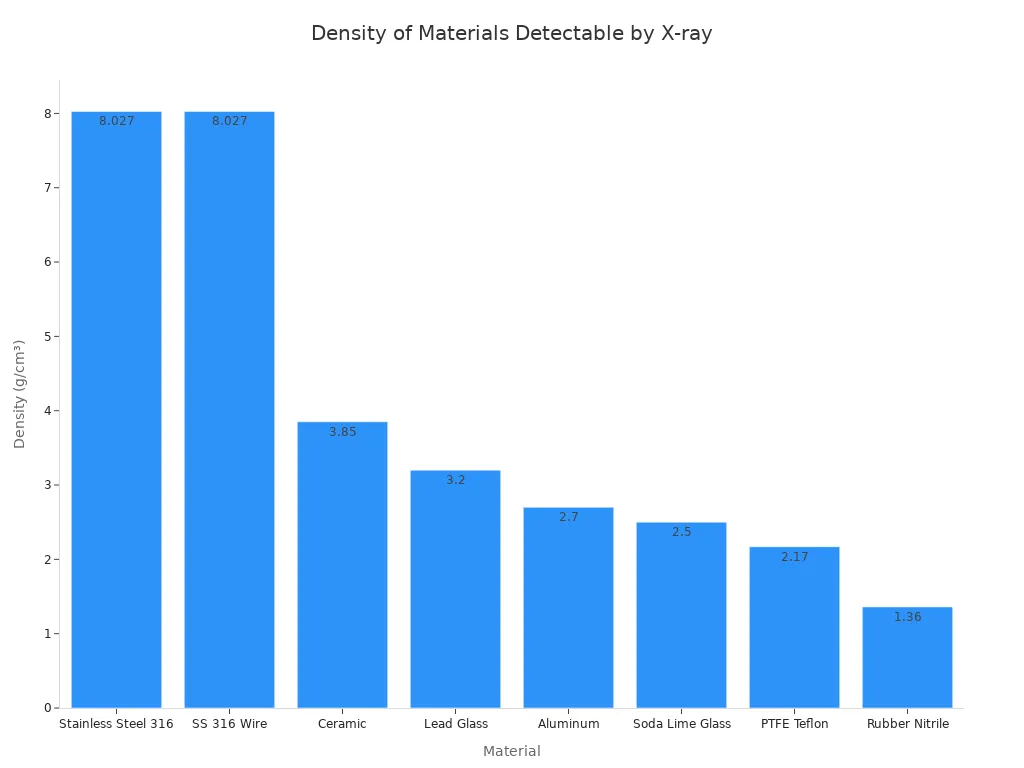

An X-ray system's effectiveness depends on the density of a foreign object relative to the food product surrounding it. The greater the density difference, the easier it is for the system to identify a contaminant. Understanding this principle helps food producers recognize both the power and the limitations of this technology.

X-ray inspection excels at finding dense foreign bodies that do not belong in food products. The technology is highly sensitive to materials that absorb significantly more X-ray energy than the food itself. This capability allows it to detect a wide range of potential physical hazards.

Commonly detected contaminants include:

Metal fragments (ferrous, non-ferrous, and stainless steel)

Glass shards

Calcified bone fragments

Mineral stones and dense rocks

High-density plastics and rubber

Modern X-ray systems can identify incredibly small contaminants. The exact size depends on the material's density. For example, a system can often find a stainless steel sphere as small as 0.6 mm but may need a glass shard to be 2 mm to ensure detection.

| Material | Density (g/cm³) | Typical Minimum Size (mm) |

|---|---|---|

| Stainless Steel 316 | 8.027 | 0.6 – 1.8 |

| Ceramic | 3.85 | 1.5 – 4 |

| Aluminum | 2.7 | 1.5 – 4 |

| Soda Lime Glass | 2.5 | 2 – 7 |

| PTFE (Teflon) | 2.2 | 2 – 7 |

| Nitrile Rubber | 1.36 | 2.4 – 7.9 |

While standard X-ray systems struggle with some plastics, advanced Material Discrimination X-ray (MDX) technology expands detection capabilities. MDX can identify certain inorganic contaminants, including specific plastics and rubbers that were historically difficult to find. This is especially true for materials containing compounds like chlorine or fluorine.

X-ray inspection technology has clear limitations based on physics. It cannot detect materials with a density that is very low or too similar to the food product being inspected. Many food products are water-based, giving them a specific gravity close to 1.0. If a contaminant has a similar density, it will absorb a similar amount of X-ray energy and become invisible to the system.

"All organic material consists of carbon, hydrogen and oxygen atoms,” said Ray Spurgeon, an expert in inspection systems. Organic contaminants such as wood and insects “look exactly like food” on X-ray display screens. If there is no difference between the bulk density and atomic characteristics of the food and the contaminant, the contaminant will most likely not be detectable.

This limitation means several common low-density materials are typically not found by X-ray systems.

| Material | Specific Gravity | Detectability Status |

|---|---|---|

| Wood | 0.65 | Typically Not Detectable |

| Insects | 0.59 | Typically Not Detectable |

| Hair | 0.32 | Typically Not Detectable |

Other undetectable materials often include:

Low-density plastics like polyethylene and polypropylene

Cardboard and paper

String and textiles

A simple rule of thumb offers a quick guide: If a material floats on water, an X-ray system probably cannot detect it. If it sinks, detection is very likely. This is because sinking indicates a higher density than water, creating the contrast needed for the X-ray system to work.

An x ray machine for food industry is a powerful tool, but questions about safety are common. Manufacturers, employees, and consumers all need assurance that the technology is safe. The science and engineering behind these systems provide clear answers, confirming their safety for both food products and personnel.

A primary concern is whether X-ray inspection affects the food itself. The radiation dose used in an x ray machine for food industry is extremely low and does not harm the product. A 1997 World Health Organization (WHO) study confirmed that radiation levels up to 10,000 gray (Gy) do not impact a food's safety or nutritional value. This dose is about ten million times stronger than the radiation used during a typical inspection.

The radiation exposure is so minimal that it does not alter the flavor, texture, or nutritional content of food. One report found that a food product could undergo over 600 million X-ray scans without any compromise to its quality.

This level of safety is distinct from food irradiation, a process that uses higher doses to sterilize or preserve food. For example, sterilizing food for NASA astronauts requires doses of 44 kGy, a level far beyond what inspection systems use. The WHO considers food irradiated up to 10 kGy to be perfectly safe and wholesome. The dose from an inspection system is a tiny fraction of that, ensuring the food remains unchanged.

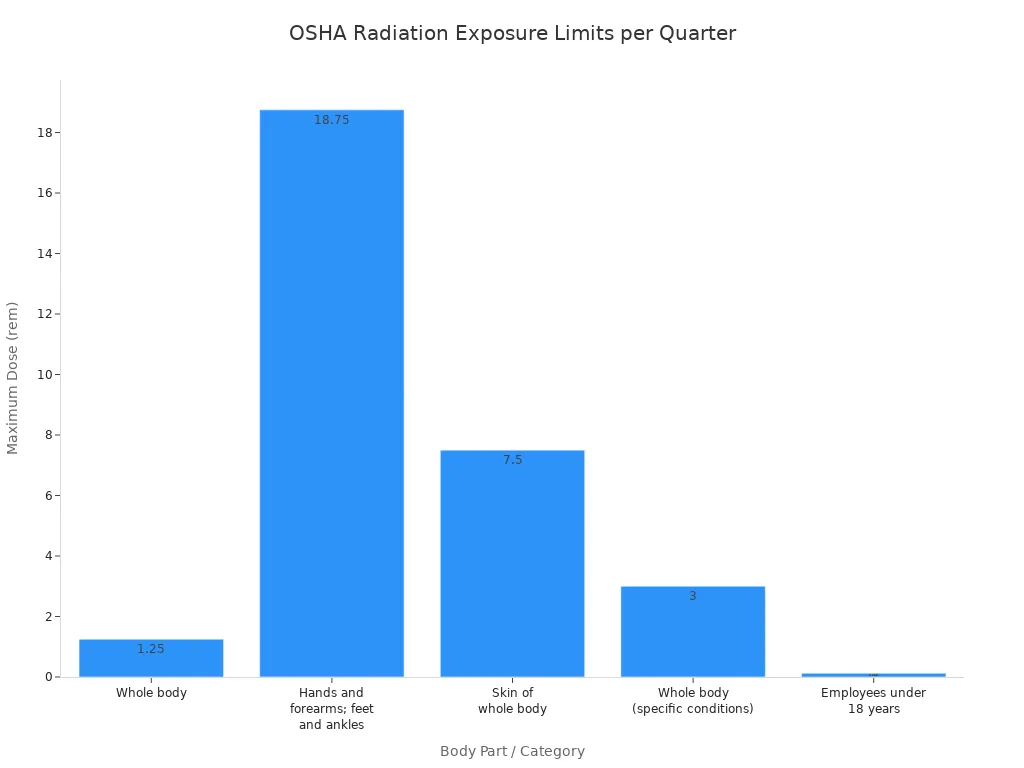

Modern X-ray inspection systems are engineered with multiple layers of protection to ensure operator safety. These machines are fully enclosed cabinets designed to contain radiation. Key safety features are built directly into the equipment to meet strict regulatory standards, like those from OSHA.

These features include:

Lead-Lined Enclosures: The cabinet is typically made of lead to keep radiation levels below 0.5 mR/hr at 5 cm from any surface.

Safety Interlocks: These devices automatically shut off the X-ray generator if a door or access panel is opened, preventing accidental exposure.

Lead-Impregnated Curtains: Multiple layers of curtains at the entry and exit points block radiation from escaping the tunnel.

Warning Systems: A visible light tower indicates when the X-ray source is active. If the light fails, the system will not allow the X-rays to turn on.

OSHA sets clear limits for occupational radiation exposure. For example, the maximum dose for the whole body is 1.25 rem per quarter. The radiation emitted from a properly functioning and maintained X-ray inspection system is well below this limit, often close to normal background radiation levels.

These integrated safety measures and strict regulations ensure that employees can work confidently and safely around X-ray inspection equipment.

Food manufacturers often face a critical decision between installing an X-ray inspection system or a metal detector. Both technologies are essential for food safety, but they operate on different principles and offer distinct advantages. Understanding these differences is key to selecting the most effective solution for a specific production environment.

The primary distinction between the two systems lies in what they can find. Metal detectors work by generating an electromagnetic field. They identify contaminants that disrupt this field. X-ray systems, on the other hand, use density to find foreign objects. This fundamental difference defines their capabilities.

X-ray inspection offers a much broader detection range. It excels at finding dense non-metallic contaminants that metal detectors cannot see at all. This includes hazards like glass, mineral stone, calcified bone, and high-density plastics. Metal detectors are limited strictly to finding metal.

Even with metals, performance varies. The orientation of a contaminant can significantly impact a metal detector's effectiveness. An X-ray system's performance remains consistent regardless of the contaminant's shape or position.

| Feature | Metal Detector Performance | X-ray System Performance |

|---|---|---|

| Wire Orientation | Detection is poor when a wire is parallel to the detector's field. | Detection is consistent regardless of wire orientation. |

| Sensitivity to Orientation | Highly sensitive, especially for elongated contaminants. | Not sensitive to orientation. |

Furthermore, the type of metal plays a crucial role. While metal detectors are excellent at finding ferrous metals, their ability to detect certain non-ferrous metals and stainless steel can be limited.

| Contaminant Type | Metal Detectors | X-ray Systems |

|---|---|---|

| Ferrous Metals (iron, steel) | Detects very well. | Detects well. |

| Non-Ferrous Metals (aluminum, brass) | Harder to detect. | Recommended for detection. |

| Stainless Steel | Difficult to detect. | Recommended for detection. |

Beyond Contaminants: An x ray machine for food industry provides additional quality assurance functions. It can measure product mass, verify fill levels, spot missing or broken items, and check for sealed-package integrity. Metal detectors cannot perform these checks.

Product packaging is a major factor where X-ray systems have a clear advantage. Many modern food products use packaging with metallic properties, such as aluminum foil or metallized film.

This type of packaging creates a large conductive signal that confuses metal detectors. To compensate, operators must reduce the detector's sensitivity. This action makes the system ineffective at finding small metal contaminants. As a result, products in metallized packaging often fail to meet the safety standards required by major retailers.

X-ray inspection systems do not have this limitation.

They operate based on density, not conductivity.

The low density of foil and metallized film poses no challenge.

X-ray systems can "see straight through" this packaging to identify denser contaminants inside.

This capability makes X-ray inspection the superior and often necessary method for ensuring the safety of products packaged in foil, metal cans, or metallized film.

Selecting the right inspection technology requires a thorough risk assessment. A food manufacturer should analyze its specific products, processes, and potential hazards to make an informed decision.

Key factors to consider in your assessment include:

Likely Contaminants: Is the primary risk from metal fragments, or could non-metallic objects like glass, stone, or plastic enter the product? If non-metallic contaminants are a concern, an X-ray system is necessary.

Product Characteristics: Products with high salt or moisture content can trigger false rejects in metal detectors due to a phenomenon called "product effect." X-ray systems are unaffected by these properties.

Packaging Type: If your product is packaged in foil, metallized film, or a metal can, an X-ray system is the only effective choice for final inspection.

Quality Assurance Needs: Do you need to verify fill levels, check for missing components, or measure product mass? Only an X-ray system can perform these additional quality checks.

Cost of Ownership: A complete analysis should include the initial purchase price plus ongoing operational and maintenance costs for both systems.

Compliance Requirements: X-ray systems provide enhanced traceability with stored images and data, which helps manufacturers comply with GFSI, BRCGS, and HACCP standards.

In some cases, the optimal solution involves using both technologies. Each system has unique strengths, and they can complement each other to create the safest possible inspection process. For example, a facility might use a metal detector to scan raw ingredients at intake and then use an X-ray system to inspect the final packaged product. This dual-system approach offers a comprehensive defense against a wide range of potential contaminants.

X-ray inspection is a powerful and versatile tool for enhancing food safety. It protects a brand's reputation by detecting a wider range of contaminants than other methods. This technology helps ensure compliance with HACCP and GFSI standards. Businesses should assess production line risks to determine if this solution fits their needs.

The cost of an x ray machine for food industry varies. It depends on system size, features, and specific application needs. A full cost analysis is recommended.

X-ray systems require regular maintenance and calibration. A manufacturer's service plan ensures optimal performance and compliance. Daily checks by operators are also standard practice.

Yes, operators need specific training. It covers safe operation, system calibration, and image analysis. Proper training ensures maximum detection accuracy and employee safety.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

UHD X-Ray detector, AI large model, all food indus...

Recommedation: Rice, wheat, corn, grain, pulses, s...

High cost performance, compact design, high sensit...

Conventional and unconventional contaminant detect...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Consumers and manufacturers alike worry about cont...

MoreX-ray inspection machines have become indispensabl...

MoreThis article delves into the persistent pain point...

MoreWhen a single shard of glass, a fragment of bone, ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis X-ray machine has revolutionized our foreign object detection process. The accuracy in identifying metal, glass, and plastic contaminants in our packaged foods is exceptional. Downtime has reduced significantly since installation.

Sarah Chen

Production SupervisorOutstanding performance in detecting bone fragments in our chicken products. The machine's sensitivity settings are precise and the user interface is incredibly intuitive. Our food safety compliance has never been better.

David Thompson

Plant ManagerHighly reliable X-ray system for our bakery line. Effectively detects stainless steel fragments and mineral stones in flour-based products. The quick calibration feature saves us valuable production time daily.

Jennifer Williams

Food Safety DirectorThis food X-ray machine provides exceptional contaminant detection for our canned vegetable products. The automatic rejection system is flawless, and the detailed reporting features have simplified our audit preparations tremendously.