Mastering Quality Control: Advanced X-ray Inspection for Nutritional and Health Products

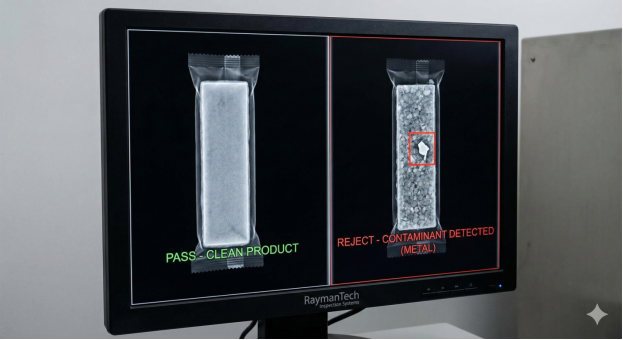

As production lines become faster and more complex, traditional inspection methods often fall short. This is where Nutraceutical X-ray Inspection Systems come into play. Leveraging advanced AI and spectral technologies, systems like those from RaymanTech provide an end-to-end solution for contaminant detection and quality assurance across the entire production chain.

Why X-ray Inspection is Critical for Nutritional and Health Products

Unlike metal detectors, which are limited to identifying metallic foreign objects, X-ray inspection systems utilize density detection. This allows manufacturers to inspect products packaged in foil or metallized film—common in Protein Bars inspection—and detect a wide range of non-metallic contaminants such as glass, stone, and dense plastics.

Below, we break down how advanced X-ray technology addresses specific challenges across different nutraceutical categories.

1. Dietary Supplements: Capsules, Tablets, and Powders

For manufacturers of high-volume supplements, even a microscopic contaminant can lead to a massive recall. RaymanTech’s systems are engineered to handle the specific risks associated with these formats:

● Tablets: The system detects metal contaminants that may originate from production line spare parts, repair welding slag, or drilling debris. It also performs defect detection, identifying damages, breaks, or cracks in individual tablets.

● Capsules: Beyond identifying metal contaminants (including fine stainless steel mesh wire), AI-powered X-ray systems check for Packaging Integrity, ensuring there are no missing grains or empty capsules within a blister pack.

● Powdered Supplements: A critical quality check for bulk powders is the detection of moisture-induced issues. Advanced systems can identify clumping (detectable if $\ge$ 10x10x10mm) and verify the integrity of seal clip materials.

2. Sports Nutrition: Protein Bars and Pre-Workout

The sports nutrition market relies heavily on dense, complex formulations. Energy Bars X ray inspection is particularly challenging due to the density of ingredients like nuts and grains, which can mimic contaminants.

● Protein Bars and Energy Bars: Intelligent algorithms distinguish between product ingredients and foreign bodies. They effectively detect metal, stone, rigid plastics, ceramics, or glass. Furthermore, the system inspects for under-formed shapes, breaks, or cracks, ensuring every bar meets aesthetic standards.

● Meal Replacement Shakes: For liquid products, X-ray systems provide Capacity Filling Control and check for contaminants like metal or stone. Crucially, for bottled products, they offer Vacuum Detection to ensure caps (including those with safety helmets) are perfectly sealed.

● Pre-Workout Supplements: In powder jars, the system not only checks for metal and rigid plastic but also performs a "component count" to ensure the inclusion of the plastic spoon or scoop—a frequent consumer complaint when missing.

3. Specialized Care: Baby Food and Infant Nutrition

There is zero margin for error when it comes to infant nutrition. RaymanTech’s solutions offer the highest sensitivity for this sensitive category:

● Baby Formula: The inspection process rigorously checks for metal (e.g., stainless steel wire mesh) and rigid plastics. It also monitors for clumping ($\ge$ 10mm) and verifies the presence of the scoop.

● Baby Food Jars and Pouches: X-ray systems can scan through glass jars to detect glass-in-glass contamination, as well as sand, stone, and ceramics. For pouches, vacuum detection ensures the product remains sterile and safe.

The RaymanTech Advantage: AI-Powered Precision

RaymanTech distinguishes itself as a high-tech enterprise specializing in spectral online detection. Their AI-Powered X-Ray Inspection Systems offer distinct advantages over standard models:

1. Reduced False Rejects: By utilizing AI deep learning, the system learns the natural variations of your product (like the texture of a granola bar), significantly reducing false alarms caused by product density differences.

2. Hygienic Design: With options for IP69K protection ratings, these machines feature a sloped, stainless steel design that is easy to wash down, preventing bacterial growth in food processing environments.

3. Virtual Weighing: The system can estimate the weight of products within the X-ray image, acting as a secondary checkweigher to prevent under-filling or over-filling.

4. Connectivity: Built for Industry 4.0, these systems support data transfer and remote support, allowing engineers to troubleshoot and optimize settings without being on-site.

Frequently Asked Questions (FAQ)

To help you better understand the capabilities of Nutraceutical X-ray Inspection Systems, we have compiled a list of common questions.

Q: Can X-ray systems inspect products packaged in aluminum foil?

A: Yes. Unlike metal detectors, X-ray inspection is not affected by metallic packaging. It is the ideal solution for Protein Bars inspection and Energy Bars X ray where foil wrappers are standard, allowing for the detection of stainless steel, ferrous, and non-ferrous metals inside the package.

Q: Is X-ray inspection safe for nutraceutical products?

A: Absolutely. The radiation dose used for industrial inspection is extremely low and does not affect the chemical composition, efficacy, flavor, or texture of dietary supplements, vitamins, or food products.

Q: Can X-ray systems detect missing items inside a container?

A: Yes. Advanced systems like those from RaymanTech can verify the presence of components inside opaque packaging. This includes checking for missing spoons in protein powder tubs or missing deoxidizer sachets in snack packages.

Q: What types of plastic can be detected?

A: X-ray detection is based on density. While low-density soft plastics (like thin film) are hard to see, rigid plastics, rubber, and dense PVC contaminants are detectable. This is crucial for identifying debris from production line spare parts.

Q: How small of a contaminant can be detected?

A: Sensitivity depends on the product density and the X-ray detector resolution. However, RaymanTech’s UHD (Ultra-High Definition) and AI-powered models are capable of detecting very small contaminants, including fine stainless steel wire mesh often found in powder processing.

Related Articles

-

Dec-12-2025

Dec-12-2025RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.learn more -

Dec-12-2025

Dec-12-2025How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about contamination in food – broken glass, metal fragments, plastic or stone – entering a product and harming someone or prompting a recall. X-ray inspection systems have become a key solution: conveyors carrying packaged or unpackaged food pass through a shielded X-ray machine that “sees” inside each item. This technology complements traditional metal detectors and manual checks to catch a wider range of hazards. Importantly, extensive research and industry experience show that food X-ray inspection is extremely safe. Nearly everything we eat – from spices to snacks – is X-rayed at some point during production, and regulatory bodies (like the FDA) report “no known adverse effects” from the low-dose X-ray scans used in food plants.learn more -

Dec-12-2025

Dec-12-2025Meat Packaging Revolution: Mastering Detection Challenges with Next-Gen X-ray and Vision Systems

This article delves into the persistent pain points in outer packaging detection for meat products, exploring the sources of demand, inherent difficulties, and how cutting-edge solutions, such as combined X-ray and visual detection systems powered by AI, are transforming the landscape. By addressing these challenges head-on, manufacturers can achieve unprecedented levels of precision, compliance, and productivity.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057