RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolv...

More

Leading manufacturers offer excellent equipment choices for 2025. The top models for small businesses are:

Tomra 3A, Bühler Sortex A-Compact, Key Technology VERYX C70, Satake FMS2000, and Raytec Dry-Sort 500.

This guide evaluates each dried apricots sorting machine based on affordability, efficiency, and user-friendly operation for growing enterprises.

Selecting the right equipment requires a careful evaluation of both technical capabilities and business needs. A business must understand what defines a quality apricot before assessing machine specifications. This ensures the chosen technology aligns with production goals and financial realities.

A high-quality dried apricots sorting machine evaluates several key attributes to meet grade standards. Businesses should prioritize machines that can accurately assess the following criteria:

Color: Top-grade apricots possess a good, characteristic color. Advanced sorters use spectrophotometers to measure brightness (L), red/green (a), and blue/yellow (b) values, ensuring consistent and appealing coloration.

Size: Uniformity in size is a critical quality marker. The machine must capably separate apricots to ensure the final product batch meets 'reasonably uniform' or 'fairly uniform' size requirements.

Moisture & Texture: Sorters can identify variations that indicate improper drying. While a specific moisture percentage is not the only factor, the machine should detect texture differences to ensure the product is not overly moist or excessively dry.

Defects: The equipment must effectively identify and remove apricots with blemishes, mold, or other imperfections to guarantee a clean and safe final product.

Beyond technical sorting, small businesses must weigh practical factors. The machine's physical footprint is a primary concern for facilities with limited space. Ease of use and maintenance requirements are also crucial to minimize downtime and the need for specialized technicians. Finally, a business must consider the financial impact.

An automated sorting solution should ideally achieve a return on investment (ROI) within two years. This makes payback period a critical metric for any small business evaluating a significant capital expenditure.

Assessing these business-specific needs helps narrow down the options to a machine that is both effective and affordable.

Choosing the right machine involves a close look at what each model offers. The following reviews break down the top five sorters, helping businesses match their specific operational needs with the best available technology.

The Tomra 3A sorter is an industry powerhouse designed for businesses that refuse to compromise on quality. It excels at high-precision sorting, making it ideal for producers targeting premium markets. The machine uses advanced imaging systems, including pulsed LED lights and cameras, to scan each apricot from multiple angles. This technology allows it to detect subtle color variations, blemishes, and foreign material with exceptional accuracy.

Its primary strength lies in its ability to remove a wide range of defects before the product moves to final packing. The Tomra 3A effectively identifies and ejects pits, stems, mold, and discolored fruit. This level of precision minimizes the need for manual inspection, increases throughput, and ensures a consistently high-grade final product. For a small business aiming to build a reputation for superior quality, the Tomra 3A provides the technological foundation to achieve that goal.

The Bühler Sortex A-Compact strikes an excellent balance between performance, size, and scalability. It is the best all-rounder for small businesses that need a high-quality sorting solution today with an eye toward future growth. This model incorporates Bühler's trusted Sortex optical sorting technology into a smaller, more accessible frame.

Pro Tip: The Sortex A-Compact is known for its modular design, which allows businesses to upgrade capabilities as their production demands increase.

The machine uses high-resolution cameras to detect defects based on color, shape, and size. Its flexible configuration can handle various capacities, making it suitable for businesses moving from manual sorting to their first automated system. The Sortex A-Compact provides the reliability and performance of a premium brand in a package that fits the operational and financial scope of a growing enterprise.

The Key Technology VERYX C70 is engineered for maximum defect removal and operational simplicity. Its standout feature is an incredibly intuitive user interface, which significantly lowers the barrier to entry for businesses without dedicated technical staff. The system is designed for unattended operation, making it a highly efficient choice.

Operators with minimal training can become proficient users in less than an hour. This is possible due to several smart features:

The system includes auto-learning and self-adjustment algorithms that adapt to product variations.

Predictive diagnostics and smart alarms, like FMAlert, notify staff of potential issues before they cause downtime.

The interface offers different views for different user levels, simplifying complex tasks.

Recipe-driven operation allows for quick, one-touch setup for different apricot grades.

This focus on usability, combined with powerful sensor technology, makes the VERYX C70 a top contender for any business prioritizing ease of use and robust defect detection.

For startups and small businesses with tight capital budgets, the Satake FMS2000 is a game-changer. Introduced as a cost-effective, full-color sorter, it delivers reliable performance at a highly accessible price point. While it may not have the multi-wavelength infrared capabilities of premium models, its RGB cameras are highly effective at sorting common defects based on color.

The "Feeder" version, introduced in 2016, adds the ability to sort by size and shape, further increasing its value. A comparison with more advanced machines highlights its position in the market.

| Feature | Satake FMS2000 | Advanced Models (e.g., Evolution Series) |

|---|---|---|

| Resolution | 0.14mm/pixel RGB cameras | Custom RGB & Multi-wavelength Infrared (MIR) |

| Application | Small to medium production, color/size defects | High-capacity sorting, challenging foreign material |

| Cost | Highly affordable | Higher investment |

This dried apricots sorting machine is an excellent entry point into automation. Furthermore, while direct leasing programs are not advertised, some distributors offer credit applications, suggesting that financing options may be available to help businesses acquire this equipment.

Space is often a luxury for small businesses. The Raytec Dry-Sort 500 directly addresses this constraint with its compact and efficient design. This machine is built to deliver powerful sorting capabilities within a minimal footprint, allowing it to fit into existing production lines without requiring a major facility overhaul.

Despite its small size, the Dry-Sort 500 uses high-resolution cameras to perform double-sided analysis of each apricot. This ensures thorough inspection for color defects, blemishes, and foreign bodies. Its user-friendly software and simple maintenance requirements make it an attractive option for businesses that need a practical, space-saving solution without sacrificing sorting quality. The machine proves that powerful performance can come in a small package.

This table provides a direct comparison of the top models. Use it to quickly assess which dried apricots sorting machine aligns best with your business's capacity, budget, and quality objectives.

| Machine Model | Best For | Capacity (kg/hr) | Price Range | Key Feature |

|---|---|---|---|---|

| Tomra 3A | High-Precision Sorting | 1,000 - 5,000 | Premium | Pulsed LED & multi-angle cameras |

| Bühler Sortex A-Compact | All-Rounder for Quality | 500 - 4,000 | Mid-to-High | Modular and scalable design |

| Key Technology VERYX C70 | Defect Removal | 1,000 - 6,000 | Mid-to-High | Intuitive, self-adjusting UI |

| Satake FMS2000 | Budget-Conscious Startups | 500 - 2,000 | Budget-Friendly | Full-color RGB sorting at low cost |

| Raytec Dry-Sort 500 | Compact Spaces | 500 - 1,500 | Mid-Range | Double-sided analysis in a small frame |

Note on Pricing: The price ranges listed (Premium, Mid-Range, etc.) are relative. High-end sorters are a significant capital investment. Always request a formal quote from a distributor for precise, up-to-date pricing.

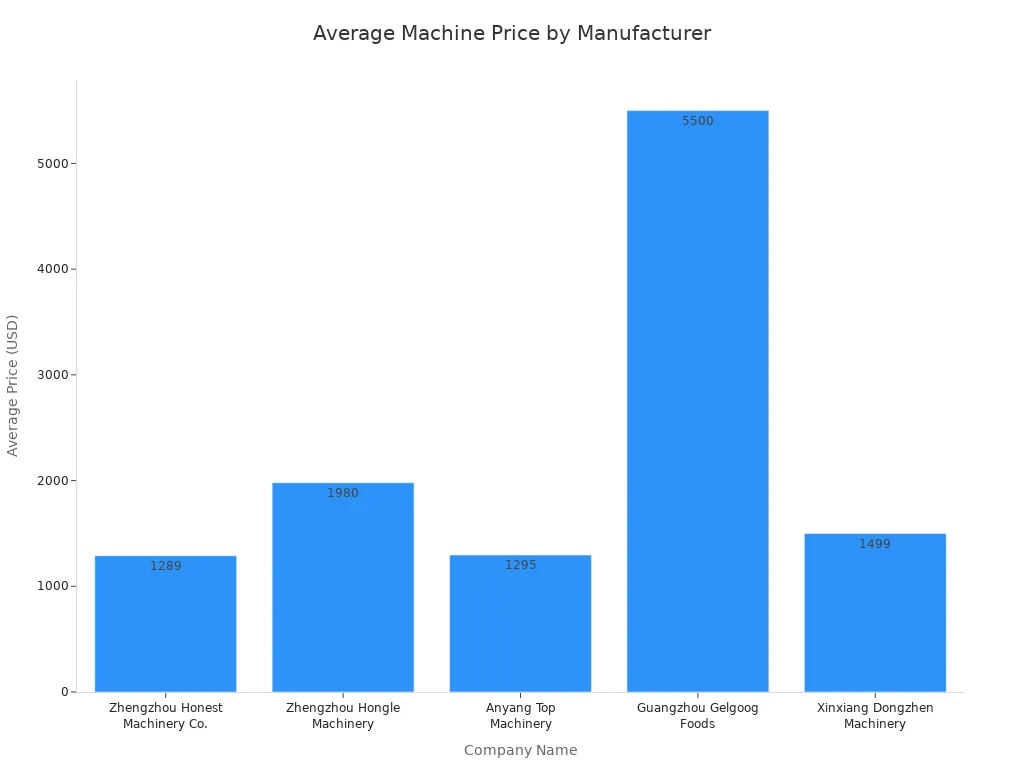

The machines in this guide represent the top tier for small but serious businesses. However, the broader market includes many manufacturers, especially at the entry-level price point. The chart below shows pricing for several other manufacturers, illustrating the cost spectrum available. These options may suit businesses with very limited capital or lower throughput needs.

Understanding this full range helps a business position its needs against its budget effectively.

For the tightest budget, the Satake FMS2000 is the clear winner. Businesses prioritizing future growth will find the Bühler Sortex A-Compact offers superior all-around performance, with a robust build and strong support ensuring long-term value. Use this guide's table to select your top contenders.

When requesting a quote for your dried apricots sorting machine, provide a clear project overview and material specifications to get the best proposal.

A business should target a return on investment (ROI) within two years. This payback period makes the capital expenditure a financially sound decision for most growing operations.

Yes, reputable manufacturers typically offer complete installation and operator training. This service ensures your team can use the new dried apricots sorting machine effectively from day one.

Premium sorters justify their cost with advanced technology. They often include infrared (IR) sensors, which detect defects like pits and foreign materials that color cameras might miss.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Both fat analysis and contaminant inspection (bone...

Recommedation: Small particle, flat products such...

Recommedation: Frozen vegetables such as green be...

Uneven and overlapped product detection, thin & lo...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Food safety and quality control demands have evolv...

MorePistachios are a premium, high-value commodity. Co...

MoreAdvanced nut sorting machine technology combines H...

MoreFor processors, the challenge is evolving. It is n...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Production SupervisorThis dried apricot sorting machine has revolutionized our production line. The optical sorting accuracy is incredible, and the throughput matches exactly what was promised. Maintenance is straightforward and downtime has been minimal.

Sarah Chen

Quality Assurance ManagerAs someone responsible for final product quality, I'm thoroughly impressed. The machine consistently removes defective apricots, stems, and foreign materials we used to miss manually. The slight learning curve for settings is why it's not a perfect 5, but it's been a game-changer for our quality standards.

David Thompson

Plant Operations ManagerOutstanding investment. The ROI was quicker than projected due to reduced labor costs for manual sorting and a significant drop in customer complaints about product quality. The build quality is robust, perfect for a demanding factory environment.

Emily Watson

OwnerFor our small organic dried fruit business, this compact sorter was the perfect solution. It's efficient, easy to operate, and has helped us maintain a consistent, high-quality product that our customers love. The support team was also very helpful during setup.