Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection an...

More

A chicken x ray machine ensures product purity. It uses low-energy x-rays to scan items on a production line. The system works by detecting density differences. Foreign materials like metal, glass, and bone absorb more x-rays than chicken meat. A sensor then creates a grayscale image. Dense contaminants appear as dark spots. Sophisticated software automatically identifies these spots and triggers a rejection mechanism, ensuring contaminated products never reach consumers.

The global market for these food safety systems is expanding rapidly. Projections show the market growing at a Compound Annual Growth Rate (CAGR) of 10% between 2025 and 2032, highlighting the industry's commitment to advanced inspection technology.

The ability of an x-ray machine to find contaminants rests on fundamental physics and advanced digital imaging. The process transforms an invisible beam of energy into a detailed density map, making the unseen visible. This technology provides a powerful tool for ensuring food safety.

The inspection process begins when a generator produces a controlled x-ray beam. This beam passes through the chicken product as it moves along the conveyor belt. As the x-rays travel, the product absorbs some of their energy in a process called attenuation. The amount of energy absorbed follows a key principle.

The Beer-Lambert Law explains this relationship. It states that x-ray attenuation increases with the material's width, density, and atomic number. Simply put, denser or thicker materials block more x-rays than less dense materials.

A sophisticated detector on the opposite side of the product captures the remaining x-rays. Modern systems use one of two primary detector technologies to accomplish this.

Indirect Conversion Detectors: These are the most common type. They use a scintillator layer to convert incoming x-rays into visible light. A photodiode array then captures this light and transforms it into an electrical signal. This method is considered the industry gold standard for its high sensitivity and excellent image quality.

Direct Conversion Detectors: These detectors use a semiconductor material, such as Cadmium Telluride (CdTe), that directly converts x-ray energy into an electrical charge. This direct conversion process offers high accuracy without the intermediate light-conversion step.

Regardless of the detector type, the resulting analog electrical signal is sent to a computer. The computer digitizes the signal, converting it into a grayscale image composed of pixels. Each pixel is assigned a shade of gray based on the intensity of the x-rays that reached that specific point. Areas where many x-rays passed through appear bright, while areas where x-rays were blocked appear dark.

The grayscale image is essentially a density map of the product. This map is the key to identifying foreign materials. Contaminants like metal, glass, and calcified bone are significantly denser than the surrounding chicken meat. They absorb a much higher percentage of the x-ray energy. Consequently, these dense objects appear as dark, distinct shapes on the bright background of the chicken, making them easy to spot.

However, the process is not without its challenges. Product characteristics can create 'busy' images that complicate analysis.

| Factor | Impact on X-Ray Image |

|---|---|

| Variable Thickness | Thicker parts of the meat absorb more x-rays, creating darker areas that can potentially hide a small contaminant. |

| Temperature Changes | Warmer products are slightly less dense than frozen or chilled ones, which can alter the overall grayscale values in the image. |

To overcome these issues, advanced systems use dual-energy technology. A standard single-energy system can struggle to distinguish a low-density contaminant from natural variations in the product. A dual-energy chicken x ray machine emits beams at two separate energy levels.

This technology allows the system to differentiate materials based on their chemical composition (or atomic number) rather than just density alone. The system's algorithms analyze the absorption at both high and low energy levels, enabling them to effectively filter out the 'noise' from the chicken product and highlight inorganic contaminants like stone, glass, and low-density plastics.

This dual-energy capability is crucial for inspecting products with high variations in density, such as seasoned chicken pieces or ready-to-eat meals. It provides a much clearer view, ensuring even small or low-density hazards are found before the product leaves the facility.

An x-ray inspection system is a powerful gatekeeper for food safety. Its effectiveness, however, depends entirely on the physical properties of the contaminant. The technology excels at finding dense foreign objects but faces limitations when contaminants closely resemble the product itself. Understanding these capabilities and boundaries is key to appreciating its role in the food industry.

X-ray systems are highly successful at identifying contaminants that are significantly denser than chicken meat. These materials absorb more x-ray energy, creating a dark, unmistakable signature on the final image.

Metal Fragments 🔩 Metal is one of the easiest contaminants to detect due to its high density. X-ray equipment readily identifies both ferrous (iron-based) and non-ferrous metals. Industry standards for meat processors typically allow for the detection of metal pieces between 1.5mm and 3mm. However, modern systems offer far greater precision. In products like chicken feet, a chicken x ray machine can locate metal fragments as small as 0.6mm. While most metals are easy to spot, some, like aluminum, are less dense and harder to find. Stainless steel, particularly types 304 and 316, presents the greatest detection challenge within the metal category.

Glass and Stone 💎 Similar to metal, glass shards and small stones are dense inorganic materials. They absorb a high amount of x-ray energy and appear as dark spots, making them relatively easy for the system's software to flag for rejection.

Bone Fragments 🦴 For boneless chicken products, bone detection is a critical safety measure. The system's ability to find bone depends on its level of calcification. Calcified bone is denser than surrounding meat and cartilage, allowing it to be identified. Advanced detector technologies, such as Eagle Product Inspection's Performance X-ray Technology (PXT™), can find calcified bone fragments as small as 1 mm. Some specialized machines can even detect bone down to 0.6 mm.

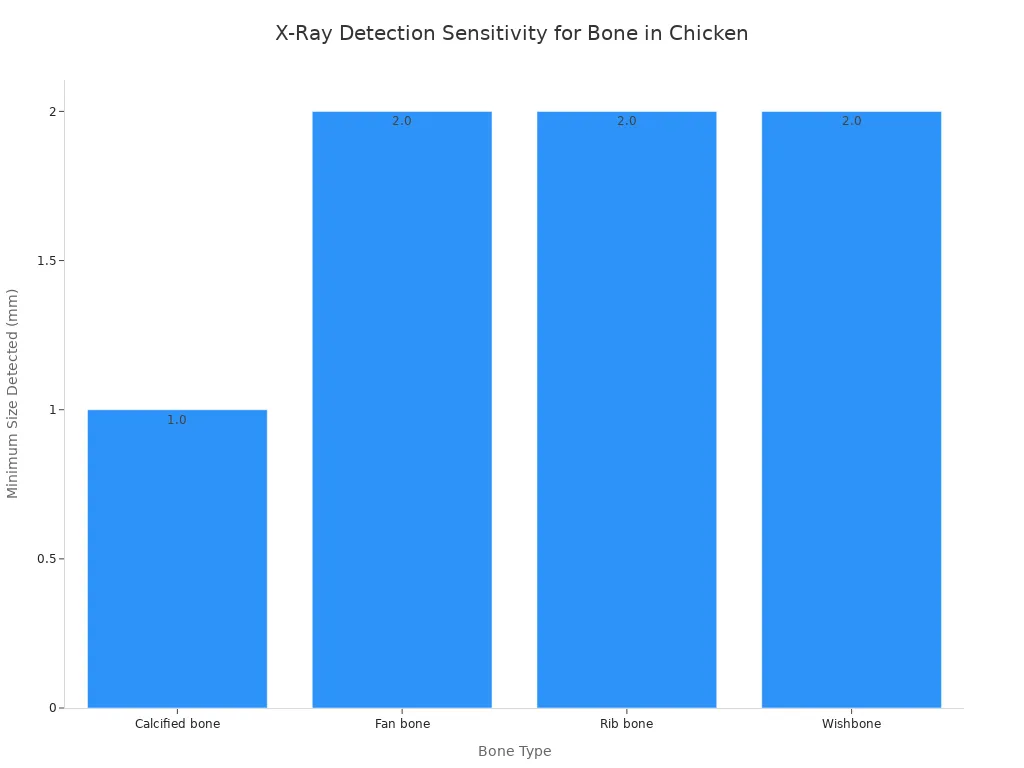

The type of bone also influences detection sensitivity. Calcified bone is the easiest to find, while other types require larger fragments to be seen.

| Bone Type | Minimum Detectable Size (mm) |

|---|---|

| Calcified bone | 1.0 |

| Fan bone | 2.0 |

| Rib bone | 2.0 |

| Wishbone | 2.0 |

Innovations continue to push these boundaries. For example, the Foodman Dual Energy X-ray Inspection System uses AI-driven algorithms and a high-resolution detector to enhance accuracy, especially for low-density bones. Despite these advances, detection is not perfect. Experiments show that while bones larger than 2 cm are found with 100% accuracy, thick fatty material can sometimes cause false positives.

The primary limitation of x-ray inspection is its reliance on density differences. When a contaminant has a density similar to the food product, it becomes nearly invisible to the system.

While standard X-ray inspection systems provide unsurpassed detection of a wide range of dense physical contaminants (stones, glass, metal), they are incapable of detecting low-density plastics and rubber in most food-based products.

This difficulty arises from basic physics. Low-density plastics like polyethylene have a density (750-950 kg/m³) very close to that of water (1000 kg/m³). Since chicken meat is composed largely of water, these plastics absorb x-rays in a nearly identical manner. The system's software cannot distinguish the faint shadow of the plastic from the natural variations in the chicken, making detection extremely difficult.

Other materials that pose a significant challenge for conventional x-ray systems include:

Wood chips or splinters

Insects

Low-density plastics (Polyethylene, Polypropylene)

Cardboard or paper

To address these gaps, the industry is exploring complementary technologies. These systems do not replace x-ray but can work alongside it to catch what it misses.

Ultrasonic Sensors: An integrated ultrasonic-inductive sensor can detect a wide range of contaminants in real-time, including magnetic metals, non-magnetic metals, and even non-metallic particles like ceramics.

Microbial Detection: Non-invasive ultrasonic techniques are also being developed to detect microbial contamination by analyzing changes in the amplitude and delay of sound waves passing through a product.

These emerging technologies highlight a commitment to comprehensive safety, aiming to create a food production environment with multiple layers of protection.

Once an x-ray system creates a density map, its sophisticated software acts as the brain of the operation. This automated safety net analyzes the image and triggers a physical mechanism to remove any contaminated product from the line, all in a fraction of a second.

The system's software analyzes each grayscale image in real-time to identify anomalies. Modern systems use deep learning, a type of AI, to enhance accuracy. These algorithms train on thousands of production images, learning to distinguish between real contaminants and acceptable product variations. This adaptability reduces false rejections.

While deep learning offers powerful adaptive capabilities, some systems also use deterministic algorithms. These provide greater control over rejection parameters, with AI often acting as a support system to catch what traditional models might miss.

To handle products with inconsistent shapes and sizes, the software can use a "Region of Interest" function. This feature allows the system to inspect individual elements of a product with specific tolerances, ensuring precise quality control without physical disassembly.

Detection is useless without effective removal. When the software flags a contaminant, it sends a signal to a rejection device. The system's logic must precisely calculate for processing latency, a delay of 5 to 10 milliseconds, to ensure the mechanism activates at the exact moment the contaminated product passes.

A chicken x ray machine uses one of several common rejection mechanisms based on product weight and line speed.

| Rejection Type | Best For |

|---|---|

| Air Jet | Lightweight products (< 1 lb) on fast lines. |

| Pusher Arm | Mid-weight products (up to 8 lbs). |

| Retracting Belt | Sturdy products that can drop into a bin. |

These high-speed systems are designed to remove only the single faulty item. This precision prevents disruption to the production flow and ensures adjacent, uncontaminated products continue on their way to the consumer.

X-ray inspection merges physics, advanced sensors, and intelligent software into a powerful food safety system.

This technology acts as a critical control point within a facility's HACCP plan. It automatically finds and removes physical hazards from chicken products.

A chicken x ray machine guarantees purity at high speeds. It provides essential protection for consumers and upholds the integrity of the food supply.

Yes, the process is completely safe. The machine uses extremely low radiation levels. This energy passes through the food without affecting its safety, taste, or nutritional value.

These systems operate at very high speeds. A typical chicken x ray machine can inspect hundreds of products per minute, easily keeping pace with modern production line demands.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

High cost performance, compact design, high sensit...

Automatic recognition and rejection, fish bone ins...

Uneven and overlapped product detection, thin & lo...

Conventional and unconventional contaminant detect...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

RaymanTech, as a leading provider of inspection an...

MoreWhy do IP65/IP67 fail in food plants? Discover the...

MoreWhen a single shard of glass, a fragment of bone, ...

MoreX-ray inspection machines have become indispensabl...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Poultry Farm ManagerThis chicken X-ray machine has revolutionized our quality control process. The image clarity is exceptional, allowing us to detect even the smallest bone fragments with precision. It's incredibly user-friendly and has significantly reduced our inspection time.

Sarah Chen

Food Safety InspectorAs a food safety professional, I'm thoroughly impressed with this equipment. The automated detection system is highly accurate, and the hygienic design makes cleaning between batches effortless. It has become an indispensable tool in our facility.

David Thompson

Processing Plant SupervisorThe machine has greatly improved our bone detection capabilities. Setup was straightforward, and the technical support team was very responsive during installation. The only minor issue was the initial calibration, but once configured, it has performed flawlessly.

Jennifer Williams

Quality Control DirectorOutstanding investment for any serious poultry processor. The dual-energy X-ray technology provides superior imaging, and the data logging feature helps us maintain comprehensive quality records. It has dramatically reduced our customer complaints about bone fragments.