Baby Food

Complete inspection and sorting for baby food manufacturing, providing strict control from source to shelf to protect product safety and upgrade food quality.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants

Baby food requires the highest standards for foreign object detection. Tiny contaminants—such as SUS sieve mesh wires, bone fragments, glass pieces or sand—can come from equipment, packaging, raw materials, or the environment. Even small foreign objects can seriously impact a baby's health, making strict safety controls essential.

UHD X-Ray and optical sorting technologies provide ultra-precise detection at critical points in production. They help manufacturers prevent hazards, avoid recalls, ensure consistent product quality, reduce waste, and protect consumer health—supporting both safety and strong market performance. -

Quality Upgrade

Advanced X-Ray inspection ensures consistent, high-quality baby food by detecting product defects such as clumping or deformation, checking seal and vacuum integrity, verifying packaging, and controlling accurate filling.

This technology helps manufacturers meet strict quality and compliance standards, reduce recalls, prevent customer complaints, and minimize waste. By improving product consistency and operational efficiency, X-Ray inspection safeguards brand reputation and supports long-term business growth and return on investment. -

Driving Long-Term Success

Infant food production demands the highest safety and precision, as even tiny contaminants or defects can pose serious health risks to babies with delicate immune systems. Ensuring ingredient purity and product consistency is essential for healthy growth.

Advanced X-Ray and optical inspection systems accurately detect and remove contaminants such as glass, metal, plastic, and stones, ensuring product safety and uniform quality. Automated inspection also ensures compliance with strict safety standards, reduces recall risks, and supports full traceability. By integrating these technologies, manufacturers can achieve safer production, consistent quality, and stronger consumer trust in the baby food market.

whole chain solution

Baby Food

• SUS Sieve Mesh Wires

• Metals, Stones, Plastics, Ceramics, Glass, Sand

• Vacuum Detection

• Discoloration and Irregular Shape

• Clumping/Agglomeration

• Correct Filling

• Spoons Missing

• Ingredients/Raw Material Inspection & Sorting

• Seal Clip

• Barcode Verification

Industrial Applications

Explore by industry - access for more information.

-

Baby Formula

More information -

Fruit/Vege/Meat Purees

More information -

Multigrain Blends

More information -

Cereal Box

More information

Get in Touch!

For your baby food inspection & sorting solutions!

Contact

For your baby food inspection & sorting solutions!

Related Machines

X-Ray Inspection Systems

Optical Sorting Systems

-

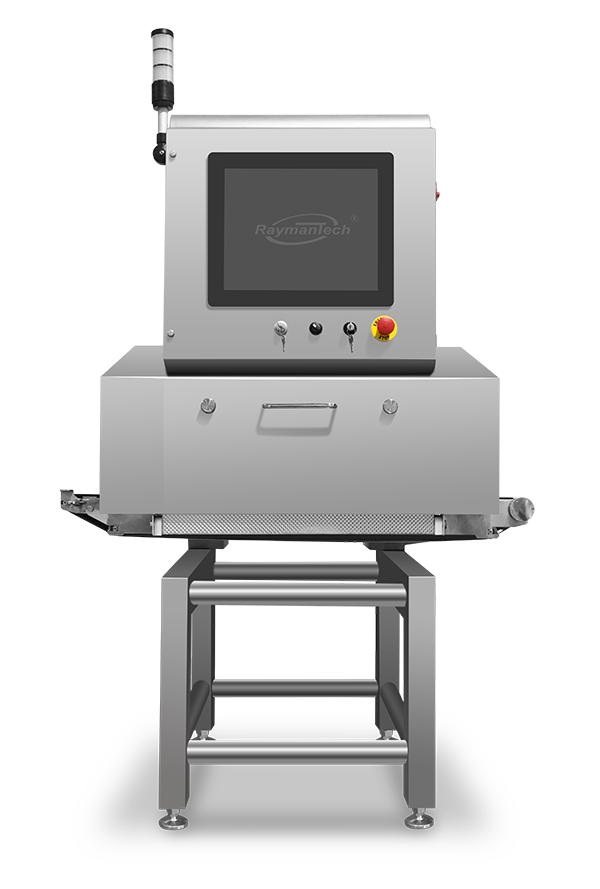

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

Standard Dual Energy X-Ray

Low-density contaminant inspection

Uneven product inspection

Thin contaminant inspection

Bone inspection

-

X-Ray for Can Bottle Jar

.png)

Metal in metal detection

Glass in glass detection

Filling level detection

Full area container detection

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use