Snack Food

Snack food inspection ensures product safety and quality by detecting contaminants, defects, missing components, imperfect packaging and barcode, etc. Suitable for snack food products in various packaging forms like pouches, trays, tubs, cans, cartons, jars, sticks, and combo packs, etc.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants

In the snack food industry, raw materials such as nuts, potatoes, and dried fruits are commonly used. During receiving, transportation, and storage, these ingredients are often exposed to contamination risks from foreign objects such as metal fragments, shell pieces, sand, or stones. In later processing and packaging stages, equipment wear, packaging damage, or operational errors can also introduce contaminants like metal, glass, or plastic, posing serious food safety concerns.

X-Ray inspection and optical sorting technologies play a vital role in safeguarding snack food safety. These systems accurately detect and efficiently remove foreign objects and impurities, ensuring high detection sensitivity and reliable quality control. By preventing contamination and protecting downstream equipment, manufacturers can meet strict safety standards, reduce operational risks and costs, and safeguard brand reputation. -

Quality Upgrade

Snack production faces various quality challenges, including poor packaging seals, missing desiccants or deoxidizers, color and shape defects (such as overcooking, breakage, cracks, or irregular forms), barcode errors, and contamination from non-compliant raw materials.

Advanced X-Ray, vision, and optical sorting technologies provide full-process quality control—from raw material handling to final inspection. These systems precisely detect appearance flaws, packaging defects, and inconsistencies in real time, ensuring every product meets strict standards. By automating inspection, manufacturers can boost efficiency, reduce human error, maintain product consistency, and deliver premium snacks that enhance brand reputation and consumer trust. -

Innovative X-Ray Solution

Aluminum foil packaging is widely used in the snack industry for its excellent sealing and barrier properties. However, as a metal material, it interferes with metal detectors, making accurate contaminant detection difficult. This challenge highlights the need for an efficient X-Ray inspection solution.

The compact smart X-Ray system is specifically designed for aluminum foil–packaged foods. Easily integrated into existing production lines, it provides real-time foreign object detection and quality control with high efficiency and minimal space. By lowering energy use and operational costs while ensuring product safety and consistency, it enables snack manufacturers to achieve safer and smarter production.

whole chain solution

Snack Food

• Metals, Stones, Plastics, Ceramics, Glass

• Discoloration and Irregular Shape

• Correct Filling of Products

• Desiccants/Deoxidizers Missing

• Ingredients & Raw Materials Inspection & Sorting

• Seal Clip

• Barcode Verification

Industrial Applications

Explore by industry - access for more information.

-

Potato Chips and Crisps

More information -

Tortilla Chips/Nachos

More information -

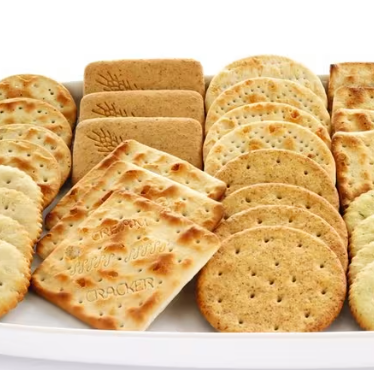

Crackers/Savory Biscuits

More information -

Nuts/Trail Mix

More information -

Candy/Chocolate Bars

More information -

Granola/Cereal Bars

More information -

Dried Fruits

More information -

Jerky

More information

Get in Touch!

For your snack food inspection & sorting solutions!

Contact

For your snack food inspection & sorting solutions!

Related Machines

X-Ray Inspection Systems

Optical Sorting Systems

-

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

X-Ray for Bulk Products

Small, tiny contaminant inspection

Low density contaminant inspection

Organic contaminant inspection

Shape inspection

Color sorting

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use