RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolv...

More

A chocolate x ray machine is a critical tool for food safety. This advanced inspection system uses low-energy X-rays to find physical contaminants and quality defects inside chocolate products. The process is non-invasive, ensuring the chocolate remains completely undamaged and safe for consumption.

A chocolate x ray machine operates through a sophisticated, two-part process involving high-speed inspection and automated removal of non-conforming products. This seamless integration of hardware and software ensures that every chocolate bar meets stringent safety and quality standards before it leaves the factory.

The journey begins when chocolate products travel on a conveyor belt through the inspection unit. Inside, a generator produces a low-energy X-ray beam that passes through each product. A detector on the opposite side captures the X-rays that make it through, creating a grayscale digital image of the chocolate's interior.

The fundamental principle at work is density differentiation.

The chocolate itself has a relatively low density, allowing most X-rays to pass through easily. This results in a lighter area on the X-ray image.

Denser materials, such as a piece of metal, glass, or a stone, absorb more X-rays. These contaminants appear as darker spots, creating a clear contrast against the chocolate.

Advanced Image Analysis in Action 💡 Modern systems utilize intelligent software to analyze these images in real time. Using AI-driven image recognition, the software learns the acceptable characteristics of a perfect product. It simultaneously checks for multiple issues, including foreign contaminants, incorrect shape, air bubbles (voids), and proper mass. When the software detects an anomaly that deviates from the pre-set quality standard, it flags the product instantly.

Once the software identifies a defective product, it sends an immediate signal to the automatic rejection system. This crucial step happens in milliseconds, ensuring the production line continues to move efficiently without interruption. The system is synchronized precisely with the conveyor's speed to target and remove only the single, flagged item, minimizing product waste.

Food production lines employ several types of rejection mechanisms, each suited for different product types and line speeds. Common systems include:

Air Jet: This device uses a sharp, powerful burst of compressed air to blow lightweight products (like individual chocolate bars) off the conveyor into a rejection bin. It is extremely fast and ideal for high-speed lines.

Pusher: A pneumatic arm with a flat plate physically pushes heavier or more stable products sideways off the line. It is a robust solution for boxed chocolates or larger items.

Swing Gate/Diverter: This mechanism uses a toggling gate to divert products onto a separate conveyor or chute. It is an excellent choice for delicate items that must remain upright.

By combining a high-precision inspection process with a reliable automatic rejection system, a chocolate x ray machine acts as a vigilant guardian on the production line, guaranteeing the final product is safe and perfectly formed.

A chocolate x ray machine offers a comprehensive inspection that goes far beyond a simple visual check. Its capabilities extend from identifying dangerous foreign objects to verifying complex quality attributes. This dual function makes it an indispensable tool for modern confectionery production, safeguarding both consumers and brand reputation.

The primary and most critical function of an X-ray inspection system is the detection of foreign matter. This refers to any extraneous material that does not belong in the final product. These contaminants can enter the production line from various sources, posing significant safety risks.

Common contaminants include:

Metal fragments from broken machinery parts

Glass shards from light fixtures or containers

Dense plastic or rubber from processing equipment like gaskets and belts

These materials present different levels of risk. A breakdown of their potential sources and the harm they can cause illustrates the importance of effective detection.

| Material | Injury Potential | Sources |

|---|---|---|

| Metal | Cuts, infection; may require surgery to remove | Machinery, fields, wire, employees |

| Glass | Cuts, bleeding; may require surgery to find or remove | Bottles, jars, light fixtures, utensils |

| Plastic | Choking, cuts, infection; may require surgery to remove | Fields, plant packaging materials, pallets |

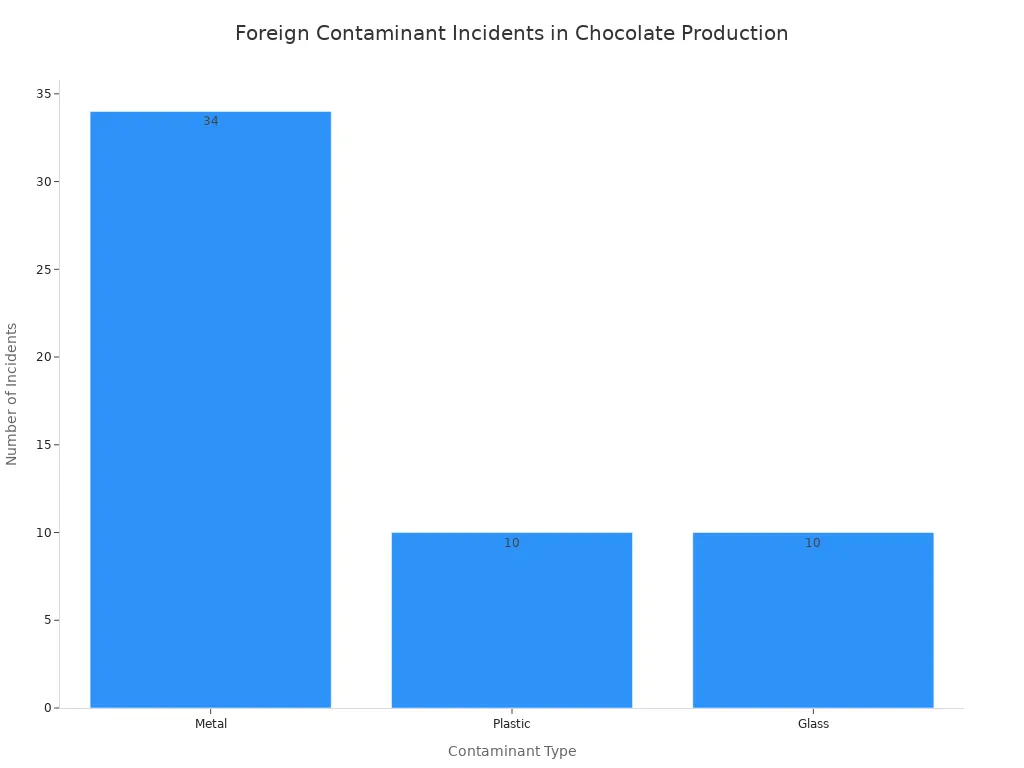

Incident reports show that metal is the most frequently found physical contaminant in food production, followed by plastic and glass.

Advanced X-ray systems can detect these dense materials with remarkable precision. The minimum detectable size can be as small as 0.3 mm, though this varies based on the product's density and packaging. The technology is sensitive enough to identify even tiny fragments that are invisible to the human eye.

| Material | Minimum Detectable Size |

|---|---|

| Stainless steel ball | Φ0.3mm |

| Stainless steel wire | Φ0.2*2mm |

| Ceramics | Φ1.0mm |

| Glass | Φ1.0mm |

Beyond finding contaminants, a chocolate x ray machine is a powerful tool for quality control. The same imaging software that spots a piece of metal can also analyze the product's internal structure and overall form. This ensures every piece of chocolate meets the brand's high standards for consistency and appearance.

Key quality checks performed by the system include:

Mass Measurement: The system can determine the weight of each individual chocolate bar, ensuring it meets the specified portion size and label claims.

Component Verification: It checks for product completeness, such as confirming a box of assorted chocolates contains every required item.

Fill Level Inspection: The technology verifies that filled chocolates have the correct amount of caramel, nougat, or cream inside.

A Deeper Look at Product Integrity 🧐 The system's software also identifies physical defects that affect quality. It can spot unwanted air bubbles (voids) within a chocolate bar, detect broken or misshapen products, and confirm the proper placement of ingredients like nuts or fruit. This guarantees the consumer receives a perfectly formed product every time.

A common question arises regarding the safety of this advanced technology. The answer is an unequivocal yes. Extensive scientific studies and regulatory approvals confirm that X-ray inspection is completely safe for both the food product and the end consumer. The process is designed to enhance safety, not compromise it.

X-ray inspection has no negative impact on the chocolate itself. The energy levels used are extremely low and the exposure time is incredibly brief, lasting only a fraction of a second. This process does not alter the chocolate's flavor, texture, color, or nutritional value in any way. The product remains entirely unchanged and perfectly safe to eat.

Global food safety standards like HACCP (Hazard Analysis and Critical Control Points) and BRC (British Retail Consortium) recognize X-ray inspection as a compliant and effective tool for quality assurance, underscoring its acceptance as a non-destructive method.

Consumers can feel confident in the safety of products inspected by X-ray systems. The food does not become radioactive and retains no residual energy. This fact is supported by leading international health organizations.

Global Regulatory Approval ✅ The use of X-ray inspection in food production is reviewed and approved by major authorities worldwide, including:

The U.S. Food and Drug Administration (FDA)

The European Food Safety Authority (EFSA)

The World Health Organization (WHO)

Furthermore, the equipment itself is built to meet strict safety regulations, such as the BRCGS Global Standard for Food Safety. Every modern chocolate x ray machine includes multiple safety features like stainless-steel shielding, radiation-blocking curtains, and automatic shut-off interlocks. These systems ensure that the equipment operates well within established radiation limits, protecting both operators and the integrity of the food supply.

A chocolate x ray machine is an essential tool for modern confectionery production. It safeguards brand reputation and public health by detecting contaminants and ensuring product integrity.

Ultimately, its function is to deliver a safer and more consistent chocolate product to the consumer, building trust with every purchase.

Yes. The system effectively inspects products through various packaging materials. Foil, plastic wrappers, and cardboard boxes do not compromise its detection accuracy.

A chocolate x ray machine operates at high speeds to match modern production lines. It inspects hundreds of products per minute without causing any delays.

The system operates automatically but requires trained personnel for setup and monitoring. This ensures optimal performance and adherence to safety protocols.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Automatic recognition and rejection, fish bone ins...

Recommedation: Frozen vegetables such as green be...

Recommedation: Aquatic products, pet food, candy, ...

Recommedation: Rice, wheat, corn, grain, pulses, s...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Food safety and quality control demands have evolv...

MoreIn the fast-paced world of food production, ensuri...

MoreRaymanTech, as a leading provider of inspection an...

MoreBone fragments are the poultry industry’s most per...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis chocolate X-ray machine has revolutionized our quality control process. Detection of foreign objects is now 100% accurate, ensuring product safety and protecting our brand reputation.

Sarah Chen

Production SupervisorThe X-ray machine integration was seamless with our existing chocolate production line. The false rejection rate is significantly lower than previous systems, though the interface could be more intuitive.

David Thompson

Food Safety SpecialistOutstanding performance in detecting metal, glass, and plastic contaminants in chocolate products. The machine's sensitivity settings are precise and the maintenance requirements are minimal.

Jennifer Williams

Plant Operations DirectorThis X-ray system has dramatically improved our production efficiency while maintaining the highest safety standards. The technical support team provided excellent installation training and ongoing assistance.