Comprehensive Introduction to IP69K Protection Rating — The Gold Standard for Equipment in Meat and Food Processing Environments

Why do IP65/IP67 fail in food plants? Discover the...

More

Metal detectors held a major market share in 2023, offering a cost-effective solution for finding metal in simple products. However, industrial digital x ray inspection systems for food are projected to lead the market by 2025. Their superior ability detects non-metal contaminants like glass and stone, making the right choice dependent on specific product risks.

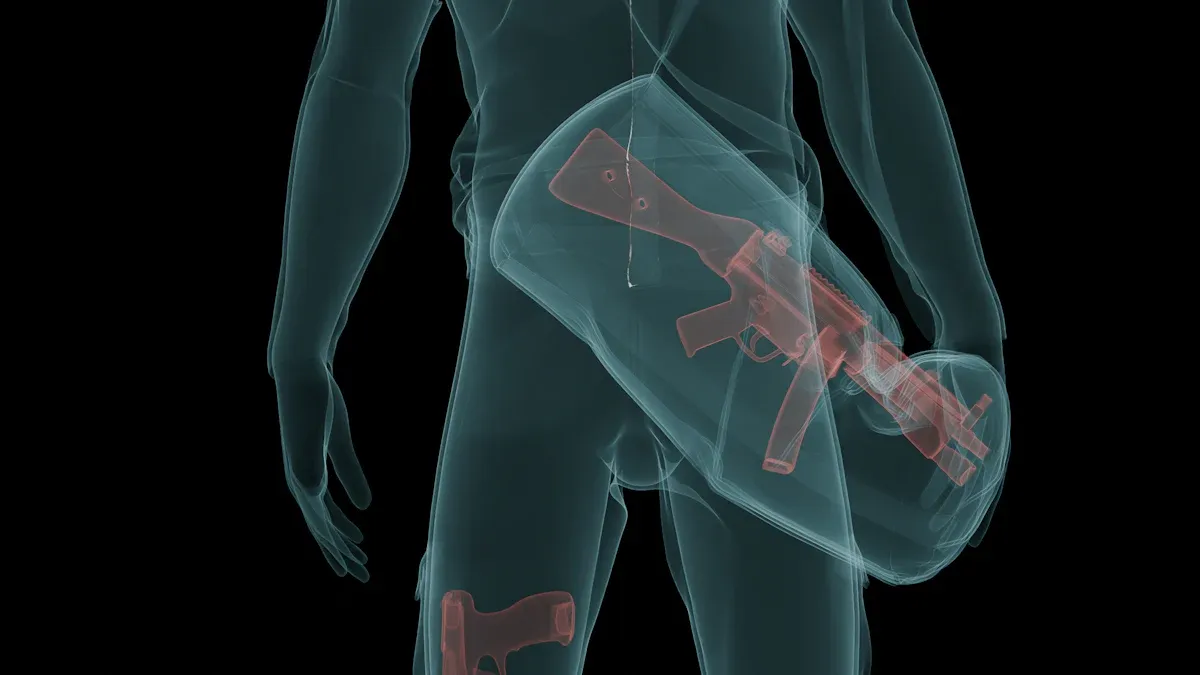

The effectiveness of an inspection system hinges on its ability to identify specific contaminants. X-ray and metal detection technologies approach this challenge from fundamentally different angles, resulting in distinct capabilities.

X-ray systems operate by identifying differences in density. This method allows them to find a broad spectrum of foreign bodies that metal detectors cannot see. They excel at locating contaminants like glass, stone, calcified bone, and even some high-density plastics. Modern industrial digital x ray inspection systems for food can spot contaminants as small as 0.3 mm, although final detection capability always depends on the product's own density and thickness. In addition to non-metals, these systems also reliably find all types of metal, including ferrous, non-ferrous, and the stainless steel grades that are challenging for metal detectors.

Metal detectors specialize in one primary task: finding metal. They create a balanced magnetic field and detect any metallic object that disrupts it. Their performance varies significantly by metal type:

Ferrous Metals (iron, steel): Easiest to detect due to strong magnetic properties.

Non-Ferrous Metals (aluminum, copper): Also detectable, but can be more challenging.

Stainless Steel: The most difficult to find. A piece of stainless steel may need to be 1.5 times larger than a ferrous sphere to trigger a detection.

A contaminant's shape and orientation also matter significantly. A thin metal wire passing through the detector in a 'worst-case' orientation can produce a very weak signal. This might cause the system to miss a contaminant that it would otherwise easily find in a different orientation.

A system's detection capabilities are not absolute. The product itself and its packaging can significantly influence inspection accuracy, creating unique challenges for both metal detectors and X-ray systems.

Metal detectors can be susceptible to something called "product effect." This issue arises when a product's own characteristics interfere with the detector's electromagnetic field.

Foods with high moisture or salt content, like cheese, seafood, and marinated meats, are naturally conductive.

This conductivity can distort the detector's signal, mimicking the presence of a metal contaminant.

The system may struggle to distinguish between the product's signal and an actual piece of metal.

This confusion leads to two potential failures: costly false rejects of perfectly safe products or, more critically, missed detections of small metal fragments.

Modern metal detectors combat this with multi-frequency or multi-spectrum technologies. These advanced systems analyze signals across multiple frequencies simultaneously, allowing them to "learn" the product's signature and effectively cancel it out to better isolate the signal of a true contaminant.

Packaging containing metal presents a major obstacle for metal detectors. Aluminum foil or metallized film packaging is inherently metallic, making it nearly impossible for a standard detector to inspect the product inside without constantly triggering an alarm.

This is where industrial digital x ray inspection systems for food demonstrate a clear advantage. X-ray technology is unaffected by foil or metallized film because it does not detect metal; it detects differences in density. The system generates a grayscale image of the product, and the low-density foil appears as a consistent background. Any denser foreign body—such as metal, glass, or stone—will show up as a darker spot on the image, allowing the system to identify it reliably.

Deciding between these technologies often involves a close look at the budget and the system's overall value. While metal detectors typically have a lower initial purchase price, a comprehensive analysis requires looking at the total cost of ownership and any additional benefits a system provides.

The initial investment is only one part of the financial equation. The total cost of ownership for an X-ray system includes several ongoing factors. A well-structured preventive maintenance plan is a critical investment to prevent costly downtime and ensure consistent performance. Running costs also contribute, based on power consumption and operational time. Furthermore, parts replacement is a significant consideration, particularly for high-power components like generators and other wear parts essential to the system's lifespan. While more complex, these costs support a highly reliable inspection process.

This is where industrial digital x ray inspection systems for food create significant additional value. A metal detector is a single-purpose tool. In contrast, an X-ray system acts as a complete quality assurance station, performing multiple checks simultaneously.

X-Ray: A Multi-Function Quality Hub ⚙️ Beyond finding contaminants, an X-ray system can:

Measure Mass: Verify product weight and identify under-filled packages.

Count Components: Ensure the correct number of items are inside a sealed box or bag.

Monitor Fill Levels: Check that bottles and jars are filled to the proper height.

Inspect Seal Integrity: Detect trapped particles in the seal area that could lead to spoilage.

This ability to consolidate multiple quality control tasks into a single inspection point delivers a powerful return on investment.

Making the right choice comes down to a clear-eyed assessment of your product, packaging, and potential hazards. An X-ray system becomes the necessary and superior choice in several specific, high-risk scenarios where metal detectors fall short.

A manufacturer's Hazard Analysis may identify significant risks beyond metal fragments. Contaminants like glass, stone, and calcified bone pose serious safety threats. An X-ray system is the only technology capable of reliably detecting these dense, non-metallic foreign bodies. The consequences of missing such contaminants can be severe, leading to widespread recalls and significant brand damage.

Real-World Recalls Caused by Glass:

Nestlé USA (2016): The company recalled nearly three million boxes of frozen pizzas and other meals after consumers found glass pieces inside. The incident resulted in millions of dollars in losses.

Labatt Brewing Company (2018): A recall of Stella Artois beer was issued across Canada due to the potential presence of glass particles, eroding consumer trust and creating a public health risk.

These incidents highlight a critical vulnerability that X-ray inspection directly addresses. For example, a Canadian condiments manufacturer successfully used an X-ray solution to mitigate risks from glass-in-glass contamination, preventing potential recalls. X-ray systems are also invaluable in upstream processing. They effectively find small mineral stones and rocks in bulk ingredients like produce or poultry before these contaminants ever reach the final packaged product.

The rise of modern packaging materials presents a significant challenge for traditional inspection methods. Many popular consumer goods rely on packaging that contains metal.

Common examples include:

Snack bars wrapped in metallized film

Coffee bags with foil linings

Potato chips and other snacks sealed in foil bags

Ready-meal trays with foil lids

A metal detector cannot inspect products inside this type of packaging. The foil or metallized film disrupts the electromagnetic field, rendering the detector unable to distinguish the packaging from a true metal contaminant. This makes effective inspection impossible. Industrial digital x ray inspection systems for food overcome this limitation entirely. Since X-ray technology detects contaminants based on density differences, the low-density foil packaging is transparent to the system, allowing it to clearly identify any denser foreign object inside.

Products with high moisture or salt content create a phenomenon known as "product effect," which can severely limit the effectiveness of metal detectors. The natural conductivity of these foods mimics a metallic signal, leading to a high rate of false rejects or forcing operators to reduce the detector's sensitivity, which increases the risk of missing a real contaminant.

X-ray inspection is immune to this product effect. It provides reliable and consistent detection for challenging product types, including:

Frozen Seafood: X-ray systems easily find bones, shells, and metal fragments in fish fillets and shrimp, even in frozen blocks with varying shapes and moisture content.

Frozen Meat and Poultry: The technology effectively locates bone fragments, metal shavings, and broken needles embedded within thick, frozen cuts of beef or chicken.

Ready-to-Eat Frozen Meals: An X-ray system inspects for foreign objects while simultaneously verifying product completeness and fill levels at high speeds.

Advanced X-ray equipment is specifically designed to maintain accuracy in harsh, low-temperature environments (below -20°C) where frost can be an issue. Furthermore, dual-energy X-ray technology enhances the detection of low-density contaminants like small bones or certain plastics, providing a level of assurance that metal detectors simply cannot offer for these complex products.

While X-ray systems offer broad capabilities, a metal detector remains a powerful and practical choice in many production environments. Its focused design provides an efficient and reliable solution when specific conditions are met, making it the ideal technology for certain applications.

A thorough Hazard Analysis is the foundation of any food safety plan. If this analysis concludes that metal is the only significant physical contaminant risk, a metal detector is the perfect tool for the job. Metal fragments can enter the production line from numerous sources, making dedicated detection essential.

Common sources of metal contamination include:

Raw Materials: Metal tags, hooks, staples, or wire mesh from bulk containers can enter with ingredients.

Processing Equipment: Wear and tear on machinery can release metal shavings, broken parts, or fragments from milling and cutting operations.

Maintenance Activities: Tools, screws, nuts, and cut wire can be accidentally left behind after equipment servicing.

A modern metal detector is highly adept at finding these threats. Its performance is precise and quantifiable, offering reliable protection against the most common metal types.

Typical Metal Detector Sensitivity 🔬 The system's ability to find a contaminant depends on the metal type and its size. Modern detectors offer impressive sensitivity levels.

Metal Type Typical Sensitivity (mm) Ferrous 1.4 - 1.5 Non-Ferrous 1.8 Stainless Steel 2.0 These measurements demonstrate a high degree of precision, ensuring that even small metal fragments are identified and removed from the production line.

Metal detectors perform at their absolute best when inspecting products that are simple, dry, and have low conductivity. These characteristics eliminate the "product effect" that challenges systems inspecting wet or salty goods. The consistent nature of these products creates a stable baseline, allowing the detector to easily spot any metallic disruption.

This makes metal detection the industry standard for a wide range of bulk and packaged dry goods. Ideal product types include:

Flour and baking powders

Sugar and spices

Rice, grains, and cereals

Pasta and noodles

Snack foods like crackers and pretzels

For these applications, a metal detector provides excellent protection without the complexity or cost of an X-ray system. Its performance is consistent, reliable, and perfectly suited to the low-risk nature of the product.

For many businesses, particularly small to medium-sized enterprises, budget is a critical factor in equipment decisions. Metal detectors typically have a significantly lower initial purchase price than X-ray systems, making them a more accessible entry point for establishing a robust food safety program.

However, a limited capital budget does not have to be a barrier to acquiring essential equipment. Many suppliers offer flexible financial solutions that help manage cash flow while ensuring product safety. These options make metal detectors an even more attainable choice.

Smart Financial Strategies for Equipment Acquisition 💰 Instead of a large upfront purchase, businesses can explore:

Equipment Leasing: Covers 100% of the equipment cost with flexible terms (e.g., 24-72 months) and buyout options. This preserves cash for other operational needs.

Financing Plans: Spreads the cost of the asset over time with predictable payments.

Rental Options: Ideal for seasonal demand, temporary production lines, or testing equipment before committing to a purchase.

These arrangements allow a company to gain the productivity and quality assurance benefits of a metal detector immediately, without straining financial resources. It is a strategic way to invest in safety and professionalism while maintaining healthy business operations.

For manufacturers seeking the highest level of brand protection, relying on a single inspection method may not be enough. Combining the strengths of both metal detection and X-ray inspection creates a comprehensive safety net that addresses a wider range of potential hazards.

A dual-system strategy provides layered, robust protection throughout the production process. Companies often place a metal detector early in the line to screen raw ingredients. This removes larger ferrous and non-ferrous metal contaminants, protecting downstream equipment like grinders and slicers from costly damage.

An industrial digital x ray inspection system for food is then installed at the end of the line as a final critical control point. This system inspects the sealed, packaged product. It finds any remaining metal fragments, including difficult-to-detect stainless steel, and also identifies non-metal threats like glass, stone, and bone. This two-step approach ensures maximum contaminant removal and product integrity.

Implementing a comprehensive inspection strategy is essential for meeting the demanding standards of major buyers. Retailers like Costco now require suppliers to use X-ray inspection technology to ensure consistent quality control. Failing to meet these mandates can result in lost business and damaged partnerships.

Furthermore, compliance with the Global Food Safety Initiative (GFSI) often requires a thorough environmental monitoring program. A dual-system approach supports this by addressing a broad spectrum of risks identified during the hazard analysis. Key elements of a GFSI-compliant program include:

Risk Assessment: Identifying and categorizing risk zones within the facility.

Systematic Sampling: Implementing strategic sampling of surfaces and equipment.

Advanced Testing: Using reliable methods to identify pathogens and spoilage organisms.

Data-Driven Insights: Employing monitoring tools to identify trends and refine safety strategies.

This level of diligence demonstrates a commitment to safety that satisfies the strictest retailer and regulatory requirements.

A manufacturer's decision begins with a Hazard Analysis to identify likely contaminants. This process involves several key steps:

Carry out a Hazard Analysis.

Identify Critical Control Points (CCPs).

Define Critical Boundaries.

Put Monitoring Protocols into Practice.

Decide on Corrective Measures.

Check the Mechanisms (Verification).

Start Record-Keeping and Documentation.

If the analysis reveals risks beyond metal, such as glass or stone, an X-ray system is necessary. A metal detector is a reliable, economical choice for simple products where metal is the only risk. For the most comprehensive protection that meets strict retailer standards, integrating both technologies provides the ideal solution.

No. X-ray systems detect contaminants based on density. They can find high-density plastics but will miss low-density plastics that are similar in density to the food product.

Both systems are effective for bulk inspection.

Metal detectors are excellent for dry goods like grains or flour.

X-ray systems reliably find stones or glass in bulk produce.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Chili, walnut, peanuts, soybeans, c...

UHD X-Ray detector, AI large model, all food indus...

Glass-in-glass / Metal-in-metal inspection, small ...

Recommedation: Frozen vegetables such as green be...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Why do IP65/IP67 fail in food plants? Discover the...

MoreAdvanced nut sorting machine technology combines H...

MoreAs pet owners increasingly view their companions a...

MoreConsumers and manufacturers alike worry about cont...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThese industrial digital X-ray systems have revolutionized our foreign object detection process. The clarity and speed of inspection have significantly reduced our false rejection rates while ensuring 100% food safety compliance.

Sarah Chen

Production SupervisorOutstanding performance in detecting bone fragments and metal contaminants in our poultry products. The automated rejection system integration has streamlined our production line while maintaining highest quality standards.

David Thompson

Food Safety DirectorHighly reliable system for continuous operation in our snack food facility. The sensitivity settings allow us to detect even the smallest contaminants without compromising production speed. Excellent technical support team.

Jennifer Williams

Operations ManagerThe dual-energy X-ray technology has been game-changing for our ready-to-eat meals. It accurately distinguishes between organic and inorganic materials, giving us complete confidence in our product safety and quality.