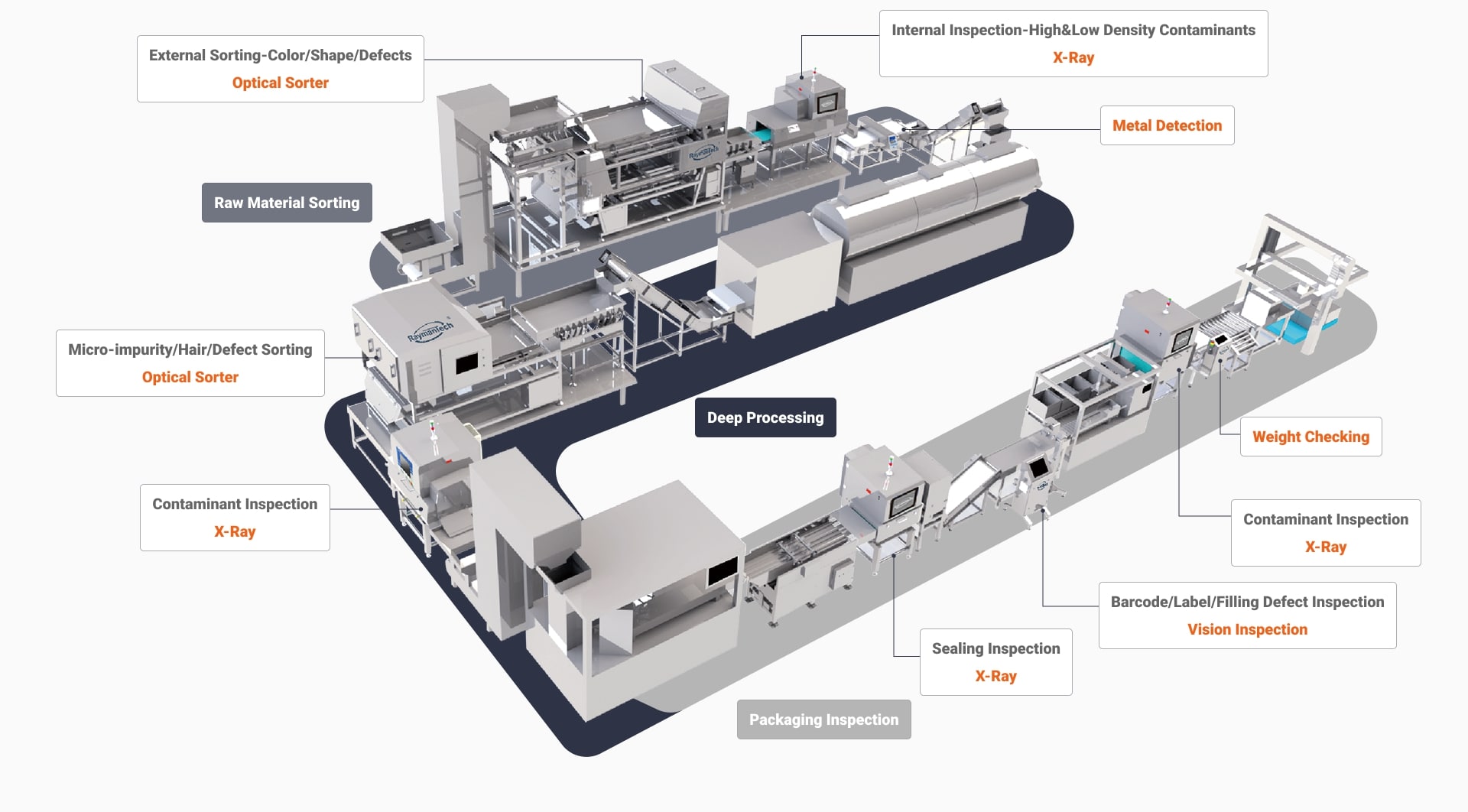

Whole Chain Inspection & Sorting All-In-One Solution

Foreign contaminant inspection system

Raw material quality sorting, grading & analysis system

Finished product appearance & defect sorting & grading system

Package seal inspection system

Packaging vision inspection system

Weight inspection & grading system

What Role Do Different Machines Play In All-In-One System

-

X-Ray Inspection System

Contaminant/defect inspection, bone inspection, seal inspection -

_1.png)

Optical Sorter

Conventional/micro contaminant sorting, color/shape/defect sorting -

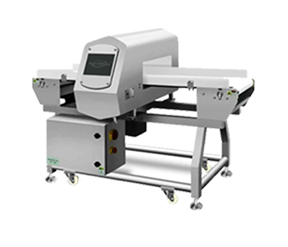

Metal Detector

Full metal contaminant detection -

Checkweigher

Product weight sorting

Get in Touch!

For tailored inspection and sorting solutions.

Contact

For tailored inspection and sorting solutions.

RaymanTech Technology Empowers End-to-End Requirements

-

Foreign Contaminant Detection:

High-density/low-density contaminants, organic contaminants, micro-impurities, etc. -

Quality Sorting:

Color, shape, surface texture, internal defects, external defects, etc. -

Quality Grading:

Grading based on weight, shape, material, appearance, etc. -

Process Sorting:

Defective products during the production process, etc. -

Composition Analysis:

Fat content, meat-to-bone ratio, etc. -

Packaging Inspection:

Inkjet code defects, heat shrink film defects, filling defects, etc. -

Sealing Inspection:

Oil leaks, false seals, wrinkles, oil stains, etc. -

Mold Detection:

Mold in raw materials like nuts, grains, etc.

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use