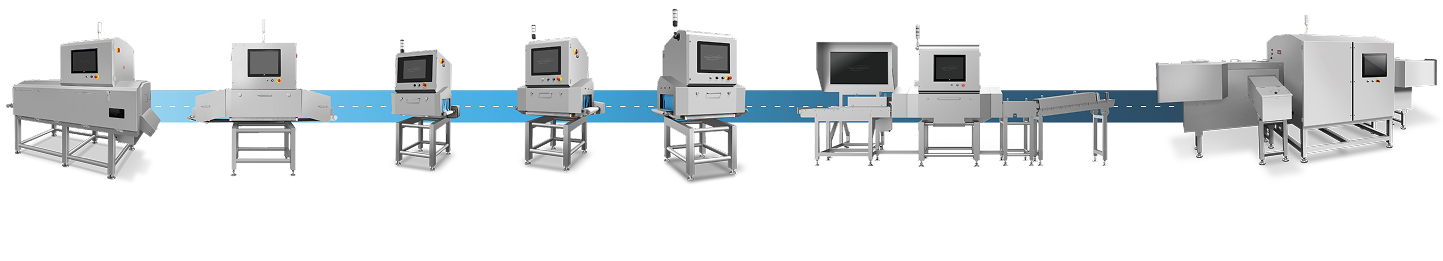

X-Ray Inspection

For Bulk Products

RaymanTech X-Ray Inspection for Bulk Products integrates X-Ray, visible light and AI-driven algorithms to detect contaminants by shape, density, material, and color. This advanced system not only identifies impurities in raw materials but also detects both internal and external defects in finished products. It precisely eliminates conventional high-density contaminants such as metal, stones and glass, as well as unconventional low-density and organic contaminants including plastics, paper, branches and leaves. In addition, it effectively recognizes defects such as wormholes, mildew, discoloration, and irregularly shaped foreign objects.

For Residual Bone/ Fat Content Analysis

RaymanTech Dual-Energy X-Ray Inspection System compares high- and low-energy images to achieve three major applications: precise residual bone detection in meats such as poultry, pork, beef, fish and etc; accurate fat content analysis to determine the fat-to-lean ratio, helping processors meet production requirements and prepare for subsequent processing or utilization; and enhanced inspection of overlapping or uneven products with the ability to detect low-density contaminants such as plastics, rubber, and paper.

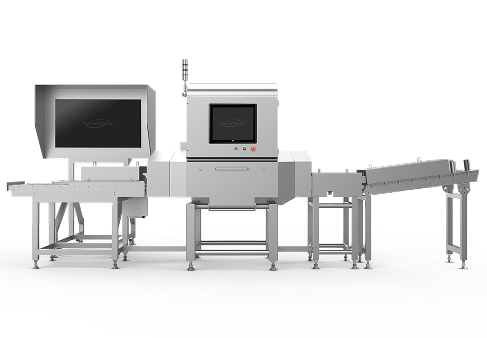

For Packaged Products

RaymanTech TOP DOWN SERIES includes the Eco, Classic, HD, and UHD models, offering a versatile range of X-Ray inspection solutions designed for efficient, high-sensitivity contamination detection with an optimal balance of affordability and performance. To meet the demands of different production environments, RaymanTech provides multiple window sizes—tunnel width ranging from small (200mm, 300mm, 400mm) to medium (500mm, 600mm) to large (800mm, 1200mm)—as well as various IP protection ratings, including IP65, IP66, IP67, and IP69K.

For Glass Bottle / Metal Can

RaymanTech X-Ray Inspection System for Bottled, Jarred & Canned Food is an advanced solution for detecting foreign contaminants such as broken glass pieces, metal shavings, ceramic, stone, and other impurities that may remain in containers during food production. Utilizing RaymanTech's self-developed multi beam imaging and AI-driven algorithm, the system ensures high-precision inspection across critical areas like bottle bodies, bottoms, screw mouths, tinplate can rings, and container edges. It is designed to handle various container types including glass bottles, metal cans, plastic cans with diverse food forms such as powders, granules, solids, semi-fluids, and liquids.

For Fish Bone

RaymanTech X-Ray Inspection System for Fish Bone is designed for online detection of hazardous and small bones that may remain in fish after processing. Utilizing advanced X-Ray imaging technology, this system ensures high-precision detection of fish bones and foreign contaminants, safeguarding product quality and consumer safety.

With a hygienic design and an IP-rated structure tailored for the fish processing environment, the system is ideal for detecting bones and foreign objects in various fish products, including halibut, salmon, basa fish, mackerel and cod. By enhancing detection accuracy and meeting strict industry hygiene standards, RaymanTech's solutions help fish processing plants streamline operations, reduce waste, and reinforce food safety compliance.

Advantages

-

Contaminant Detection

Detects metal (ferrous, non-ferrous, stainless steel) and non-metal (glass, bone, stone, plastic) contaminants. -

Quality Control

High-resolution imaging system and intelligent software enable precise inspection of fat content, density variations, product defects, seal integrity, and missing items. -

AI-Powered Detection

Customized AI for spectral analysis, enabling detection of unconventional contaminants, shape recognition and more. -

Packaging Inspection

Supports all retail formats: foil/plastic containers, cartons, bags, trays, sachets, PET bottles, cans, jars, etc. -

Easy Operation

User-friendly design with one-click start, multi-language support, easy integration, and multiple connectivity interfaces. -

Structure Design

Modular design allows component sharing across models, simplifying maintenance and reducing costs.

Industry

Dried Fruits

Dried Fruits

Color and shape sorting

Defect detection

Damaged or deformed product rejection

Confectionery

Confectionery

Overlapping and sticky candy inspection

Product missing detection

Tiny contaminant detection

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

.png)