How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about cont...

More

Foreign material contamination is a primary cause of U.S. food recalls. Statistics identify metal as the leading physical contaminant, causing 36% of these incidents. Producers often choose metal detectors for simple, dry goods. A real time x ray machine for food better handles complex items, detecting metal, glass, and bone.

Selecting the right inspection system requires a careful risk assessment. The decision between a metal detector and an X-ray machine hinges on four critical questions about your production line. Answering them will guide you to the most effective and economical solution for protecting your products and brand.

The first step is to identify your most likely contaminants. A system's value depends entirely on its ability to find the foreign materials that pose a risk to your specific product.

Metal detectors excel at finding metallic objects. High automation in food plants means processing equipment is a primary source of contamination. Inadequate maintenance can introduce metal fragments into the product flow. Common metallic contaminants include:

Ferrous metals (carbon steel)

Non-ferrous metals (aluminum, copper, brass)

Stainless steel (detection varies by grade and properties)

Incidental hardware like screws, staples, nuts, and bolts

If your risk assessment concludes that metal is the only significant physical hazard, a metal detector is a strong and cost-effective choice.

However, many other contaminants can compromise food safety. X-ray systems detect foreign bodies based on density differences. They can identify a much broader range of materials that metal detectors will miss. These non-metallic contaminants often include:

Glass: Shards from containers or light fixtures.

Stone: Rocks and pebbles introduced during harvesting.

Bone: Calcified fragments in meat, poultry, and fish products.

High-Density Plastics and Rubber: Pieces from machinery components like gaskets or paddles.

Wood and Cardboard: Splinters from pallets or packaging.

Note: If your product has a known risk of contamination from glass, dense plastics, or mineral stone, an X-ray inspection system is the only reliable technology to detect these threats.

Product characteristics and packaging materials significantly impact inspection system performance. This factor, known as the "product effect," can render some technologies ineffective.

Metal detectors work by sensing disruptions in an electromagnetic field. Products with high moisture or salt content, such as meat, poultry, cheese, and sauces, are naturally conductive. This conductivity can interfere with the detector's field, mimicking a metal signal and causing a high rate of false rejections. This interference may also mask the signal of a real metal contaminant, allowing it to pass undetected.

Packaging presents another major challenge. While metal detectors can inspect products in simple plastic or paper, certain materials block their electromagnetic fields.

Metallized Film: This packaging creates a large signal that forces conventional metal detectors to operate at a lower sensitivity, reducing their effectiveness.

Aluminum Foil: Standard metal detectors cannot inspect products packaged in aluminum foil trays or wraps. Specialized "ferrous-in-foil" detectors exist, but they can only find iron-based metals, leaving the product vulnerable to stainless steel or non-ferrous contaminants.

X-ray inspection systems are generally unaffected by product moisture, salt content, or packaging like metallized film and foil, making them the superior choice for these challenging applications.

Budget is a practical consideration that involves both initial investment and long-term operational costs. A clear cost-benefit analysis is essential.

Industrial food-grade metal detectors represent a lower initial capital investment. Their simpler technology and manufacturing process make them a more accessible entry point for many producers.

X-ray inspection systems require a significantly higher upfront cost. The sophisticated technology involved means purchase prices typically range from $60,000 to over $500,000, depending on the system's size and features.

However, the total cost of ownership extends beyond the purchase price. A comparison of long-term costs reveals a more complex picture.

| Feature | X-Ray Machines | Metal Detectors |

|---|---|---|

| Initial Cost | Higher | Lower |

| Operational Costs | Higher (energy, cooling) | Lower |

| Maintenance | Higher (periodic tube replacement) | Lower (fewer critical components) |

| Lifespan | Shorter (faster depreciation) | Longer (slower depreciation) |

Producers must weigh the lower initial cost of a metal detector against the broader detection capabilities and quality control functions of an X-ray system to determine the best return on investment for their operation.

Modern inspection systems can do more than just find contaminants. If your quality assurance program requires checks beyond foreign material detection, an X-ray system offers multifunctional capabilities that provide immense value.

A metal detector performs one job: it detects metal.

In contrast, a real time x ray machine for food acts as a comprehensive quality assurance station. By analyzing a product's density through a digital image, it can perform numerous simultaneous checks on every item passing through the line. These additional functions include:

Mass Measurement: Verifying the weight of each product.

Component Count: Ensuring all items are present in a multi-pack.

Fill Level Monitoring: Checking that containers are filled to the correct level.

Shape and Integrity Checks: Identifying broken, misshapen, or incomplete products.

Package Integrity: Inspecting for damaged packaging or compromised seals.

Position Check: Confirming the placement of components within a package.

Leveraging a real time x ray machine for food for these quality checks can streamline production, reduce product giveaway, ensure consistency, and protect brand reputation by preventing imperfect products from reaching the market. This added functionality can provide a rapid return on the initial investment.

A metal detector is a reliable and economical choice when your primary risk is metallic contamination. Understanding its operation, strengths, and limitations helps determine if it is the right fit for your production line.

Most food-grade metal detectors use a balanced coil system. This technology offers high sensitivity for a wide range of applications. The process is straightforward:

A central transmitter coil generates a stable electromagnetic field.

Two receiver coils on either side are balanced to produce a net zero signal.

A metal contaminant passing through disturbs this field.

The disturbance unbalances the coils, creating an offset signal.

Electronics amplify this signal, triggering a rejection mechanism if it exceeds a set threshold.

Metal detectors offer a lower initial investment compared to X-ray systems. They are also known for their robust construction and long operational life. While a specific lifespan varies, longevity depends on proper care. Regular maintenance is key to ensuring optimal performance. Key checks include:

Verifying calibration for accuracy.

Testing the signal response with different metals.

Inspecting electrical components and connections.

The primary limitation of metal detectors is the "product effect." This occurs when a product's own characteristics, like high moisture or salt content, interfere with the electromagnetic field. This interference can mimic a metal signal, causing false rejections or masking a real contaminant.

The product effect makes it difficult for the detector to distinguish between the food itself and a metal fragment.

Foods with a strong product effect include meat, poultry, dairy products, and even hot baked goods.

Metal detectors perform exceptionally well with products that have low moisture and conductivity. They are the ideal solution for inspecting typically-inert snack foods, confectionery items, cereals, and dry baked goods.

These systems are also highly effective for bulk-flow applications. Gravity-fed detectors inspect free-flowing powders, grains, and nuts before final packaging. Integrated conveyor systems provide seamless inspection for bulk items, detecting contaminants with high accuracy without disrupting the production flow.

An X-ray machine is the superior choice for comprehensive safety and quality assurance, especially for complex products. It offers detection capabilities far beyond those of a metal detector, justifying its higher investment for many modern food producers.

X-ray inspection systems identify contaminants based on density. The machine generates X-rays and passes them through a product. A sensor on the opposite side measures the amount of X-ray energy that is absorbed.

Denser materials, like metal, glass, or stone, absorb more X-rays than the surrounding food. This difference creates a contrast in the resulting digital image, allowing the system to flag the item as contaminated.

Advanced systems can even use dual-energy technology to find lower-density contaminants like plastic or cartilage.

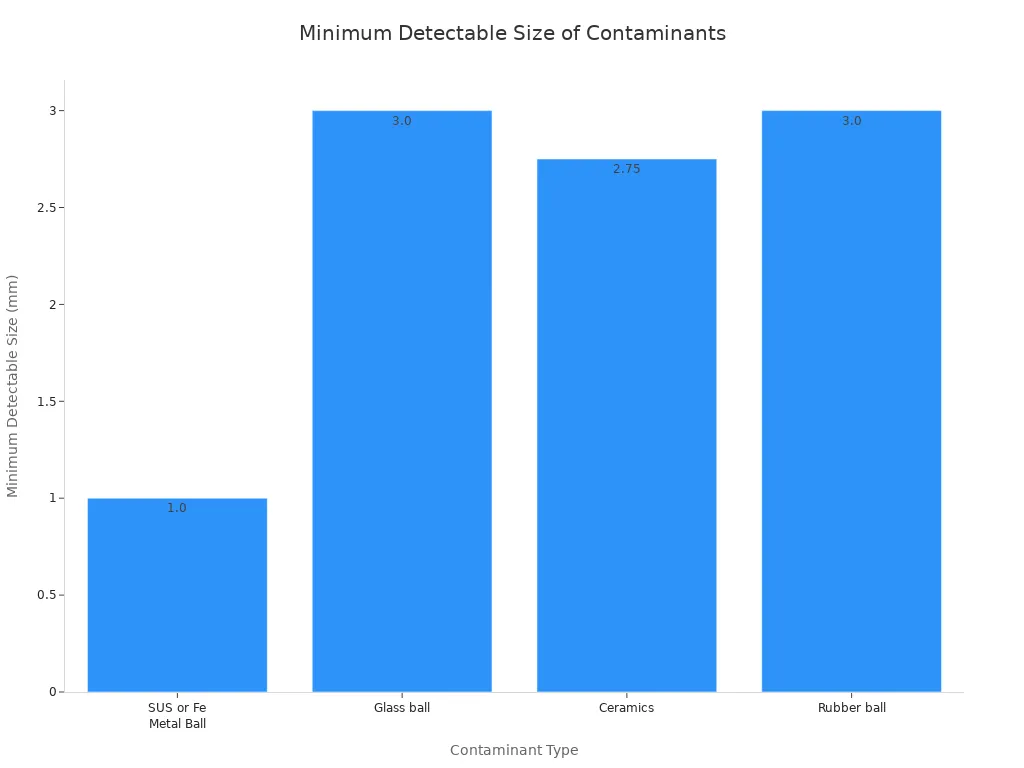

The primary strength of an X-ray system is its ability to find a wide range of foreign materials. While metal detectors only find metal, X-ray machines can identify many other physical hazards. This versatility provides a much stronger safety net. Modern systems can reliably detect contaminants down to very small sizes.

A real time x ray machine for food integrates directly into the production line. It inspects 100% of products at high speeds without causing bottlenecks. This capability allows for immediate process control. If the system detects a recurring issue, operators can stop the line and fix the problem source quickly. This immediate feedback from a real time x ray machine for food minimizes waste and prevents large-scale contamination events.

X-ray inspection is ideal for products that challenge metal detectors. It excels with items that have high moisture or salt content. It is also the best solution for products in metallic packaging. A real time x ray machine for food is perfectly suited for:

Ready-to-eat meals in foil trays

Convenience foods and food-to-go

Sauces, soups, and other fluid products

For maximum protection, the most robust food safety programs do not choose one system over the other. Instead, they deploy both metal detectors and X-ray machines at different stages of production. This layered defense creates a comprehensive safety net that addresses a wider range of potential risks.

A successful strategy begins with a Hazard Analysis and Critical Control Points (HACCP) plan. This plan identifies specific points in the production line where hazards can be prevented or eliminated. Processors determine CCPs by analyzing each step for potential physical contamination.

A hazard analysis first identifies potential foreign bodies.

CCPs are then established where controls can effectively reduce these hazards.

A metal detector after a grinder is a common CCP for metal fragments.

An X-ray system after bottling is a CCP for glass shards.

A dual-system approach often involves inspecting materials at both the beginning and end of the line. Inspecting raw materials is a highly effective strategy. It protects expensive downstream equipment from damage and prevents widespread contamination before it starts. For example, a dairy processor might use a metal detector to inspect 25-pound increments of shredded cheese before it is bagged.

Final product inspection is the last line of defense. It catches contaminants introduced during processing or packaging.

After a product is sealed in cryovac packaging, a final quality check is essential. An X-ray system can perform this check, inspecting for foreign bodies while also verifying seal integrity and fill level.

Combining technologies provides the highest level of food safety. A metal detector at the raw material stage offers an economical way to remove the most common physical hazard—metal. An X-ray machine at the final packaging stage then finds non-metallic contaminants and performs critical quality checks. This comprehensive approach minimizes risk, protects brand reputation, and ensures consumer trust. 🛡️

Choosing the right system comes down to a direct comparison of capabilities. This summary breaks down the key differences to help guide your decision.

The primary difference lies in the types of foreign materials each system can find. X-ray systems offer a broader detection range, while metal detectors are specialized.

| Feature | Metal Detector | X-ray System |

|---|---|---|

| Detects Metal | ✅ Yes | ✅ Yes |

| Detects Glass | ❌ No | ✅ Yes |

| Detects Stone/Bone | ❌ No | ✅ Yes |

| Detects Dense Plastic | ❌ No | ✅ Yes |

A metal detector is designed specifically for metallic objects. An X-ray system provides more comprehensive protection by identifying non-metallic threats like glass, stone, and bone.

Product characteristics and packaging materials heavily influence system performance.

Metal Detectors: These perform best with dry, non-conductive products like cereals and powders. High moisture, salt content, or foil packaging can interfere with their electromagnetic fields, causing false alarms or missed contaminants.

X-ray Machines: These systems are unaffected by moisture, salt, or foil. They are the ideal choice for inspecting ready meals, dairy products, sauces, and items in metallized film.

Budget is a critical factor, but it includes more than the initial purchase price.

Metal Detectors: They have a lower upfront cost and are generally easier to maintain. This makes them a more affordable entry-point solution.

X-ray Machines: These systems require a higher initial investment. However, this cost can be offset by preventing costly recalls and protecting brand reputation from a wider range of contaminants. Total cost also includes factors like training, maintenance, and potential downtime.

Modern inspection technology can offer value beyond simple contaminant detection.

Metal Detectors: Perform a single function: finding metal.

X-ray Machines: A real time x ray machine for food serves as an all-in-one quality control station. It can simultaneously:

Measure product mass or weight.

Count components within a package.

Verify fill levels in containers.

Check for damaged or misshapen products.

Inspect for compromised package seals.

These extra functions help reduce product giveaway and ensure overall product quality.

A thorough risk assessment guides the final decision. It analyzes the specific product, potential contaminants, and packaging. Metal detectors offer a reliable, economical solution for metal-only risks in suitable products. X-ray machines provide a comprehensive safety net and add significant quality control value. Proper validation ensures either system performs as intended.

Yes, X-ray inspection is completely safe for food products. The low energy levels do not affect the food's safety, flavor, or texture. It remains perfectly safe for consumption.

X-ray systems cannot find every contaminant. They detect foreign bodies based on density differences. Low-density items like hair, paper, or certain plastics may go undetected by the system.

A metal detector offers a cost-effective solution for metal-only risks. An X-ray machine provides broader protection but requires a higher investment. A risk assessment determines the best choice.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Both fat analysis and contaminant inspection (bone...

Recommedation: Aquatic products, pet food, candy, ...

Conventional and unconventional contaminant detect...

Ultra-fine contaminants detection, UHD X-Ray detec...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Consumers and manufacturers alike worry about cont...

MoreX-ray inspection machines have become indispensabl...

MoreThis article delves into the persistent pain point...

MoreWhen a single shard of glass, a fragment of bone, ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis real-time X-ray machine has revolutionized our food inspection process. The detection accuracy for contaminants like metal fragments and glass shards is exceptional, significantly reducing our product recall risks.

Sarah Chen

Production SupervisorImpressive performance in detecting bone fragments in our poultry products. The real-time imaging allows immediate line adjustments, though the initial setup required some technical support. Overall, a valuable investment for food safety.

James Wilson

Food Safety DirectorOutstanding machine that provides crystal-clear imaging of packaged products. The automatic rejection system integrated with our conveyor belt has improved our inspection efficiency by 40% while maintaining zero false positives.

Emily Thompson

Plant ManagerThe real-time X-ray system consistently identifies density variations in our baked goods with remarkable precision. User interface is intuitive, and the maintenance support has been responsive. Minor calibration needed during shift changes.