Safe Paws, Happy Hearts: Mastering Pet Food Safety with Advanced X-Ray Inspection

As pet owners increasingly view their companions a...

More

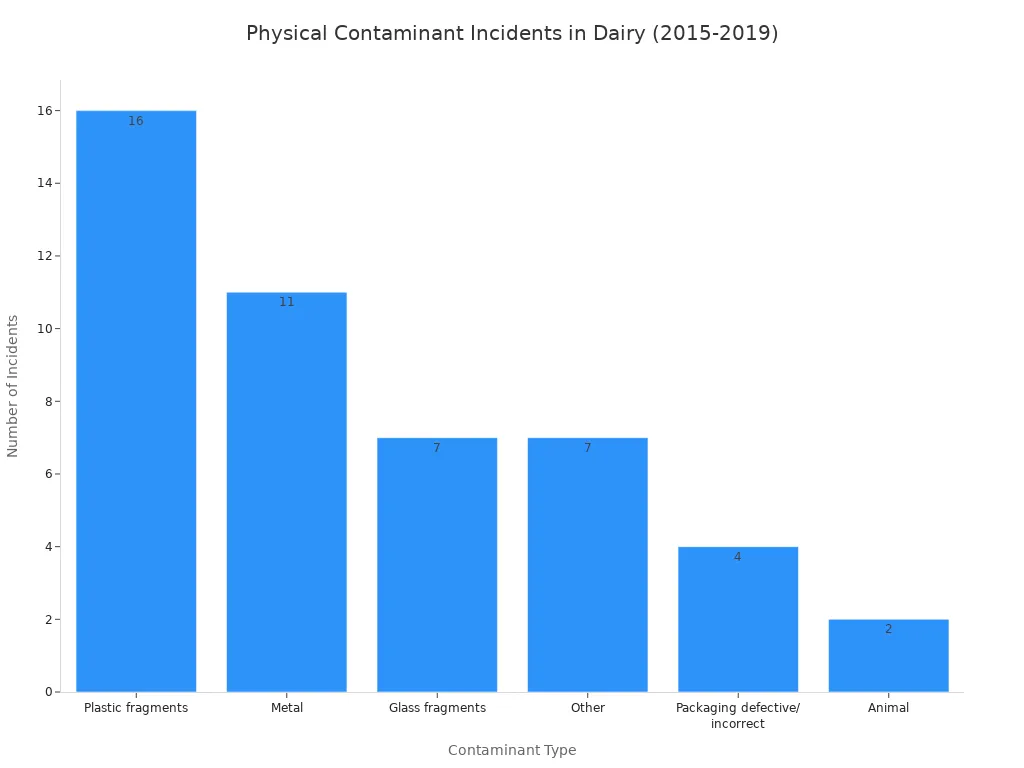

Physical contaminants like metal and plastic commonly enter the dairy supply chain. These foreign bodies create serious health risks and damage brand reputations. A study of incidents from 2015-2019 highlights the frequency of this threat, making tools like a cheese x ray machine essential for consumer safety.

| Contaminant Type | Number of Incidents (2015-2019) |

|---|---|

| Plastic | 16 |

| Metal | 11 |

| Glass | 7 |

| Other | 7 |

| Animal | 2 |

Health Risks from Contaminants: Ingesting foreign materials can lead to severe consequences, including oral injury, tooth damage, asphyxiation, and internal bleeding.

Brittle contaminants like metal, glass, and stone present a severe physical hazard in dairy products. These dense materials can cause significant harm if ingested. Understanding their origins is the first step toward effective prevention and detection.

Metal is a frequent contaminant in dairy processing. It often originates directly from the equipment used to produce cheese, milk, and yogurt. Common sources include:

Wear and abrasion from machinery parts, especially when processing abrasive products like lactose.

Breakdowns of equipment, such as pump failures or screen breakages.

Accidental introduction during maintenance activities or from contaminated raw materials.

In one case, a cheese manufacturer initiated a recall due to potential metal fragments found in a raw material from a supplier. This highlights how contamination can enter the supply chain at any stage. A high-sensitivity cheese x ray machine can effectively identify these metallic fragments before products reach consumers.

Glass poses a critical risk due to its potential for causing serious injury. Federal regulations mandate strict controls to prevent glass contamination.

The U.S. Code of Federal Regulations requires facilities to use safety-type light bulbs, fixtures, and skylights over exposed food. This measure helps protect products from contamination in case of breakage. (21 C.F.R. § 110.20)

Breakage can occur from light fixtures, gauge covers, or glass packaging on the line. Facilities must implement comprehensive glass control policies, including regular audits and immediate cleanup protocols, to mitigate this threat.

Stones, pebbles, and ceramic fragments are less common but still dangerous. These contaminants typically enter the facility with raw agricultural ingredients. They can be inadvertently harvested with crops used in flavored yogurts or get mixed into animal feed, eventually finding their way into the raw milk supply. Advanced detection systems are crucial for identifying and removing these dense foreign objects.

Low-density materials like plastics, rubber, and wood are some of the most common and challenging contaminants in the dairy industry. Their elusive nature makes them difficult to detect with traditional methods, posing a persistent risk.

Plastic and rubber fragments often come from processing and packaging equipment. Scrapers, gaskets, seals, and conveyor belts can degrade over time, shedding small pieces into products. One food processor experienced this issue when plastic scrapers in mixers broke apart. Rubber seals on equipment lids also degraded, contaminating the product stream. The company solved this by switching to materials specifically designed for detection. A modern cheese x ray machine can identify many dense plastics and rubbers, but preventing their entry is the primary goal.

Wood splinters from pallets, crates, or building materials can accidentally fall into production lines. These low-density organic materials present a significant detection challenge. Traditional X-ray systems find it difficult to spot wood, often rendering it "virtually invisible" within a food product. This invisibility makes wood fragments a frequent cause of consumer complaints, as they can easily pass through standard quality checks. Advanced inspection technologies are necessary to locate such elusive foreign bodies.

Bone fragments are another organic contaminant. They can enter the raw milk supply if an animal has a healed injury or can be introduced through other animal-derived ingredients. Unlike wood, calcified bone is dense. This density makes it much easier to identify. An effective cheese x ray machine can readily detect these fragments, helping manufacturers ensure the final product is free from such hazards before it reaches the consumer.

While traditional methods have their place, they leave significant gaps in a modern food safety plan. An X-ray inspection system offers a comprehensive solution. It addresses the limitations of older technologies and provides multifaceted benefits that protect products, consumers, and the brand itself. This technology is becoming the preferred method for factories adhering to strict retailer codes of practice.

Metal detectors operate using electromagnetic fields. They are effective at finding conductive materials but struggle with contaminants that do not interact with these fields. A cheese x ray machine operates on a different principle: density. It identifies foreign bodies by detecting differences in density between the contaminant and the surrounding product.

This technological advantage allows X-ray systems to find a much wider range of physical hazards.

Glass shards and ceramic fragments

Stones and pebbles

Calcified bone

Dense plastics and rubber

Gasket materials

The high moisture and salt content in dairy products can create a "product effect" that challenges metal detectors, making it harder to find small metal fragments. X-ray inspection is not affected by these properties, offering more reliable detection in products like cheese and yogurt.

| Feature | X-ray Inspection | Metal Detector |

|---|---|---|

| Detection Principle | Density differentiation | Electromagnetic conductivity |

| Effect of Moisture/Salt | Minimal impact | Increases product signal, can mask contaminants |

| Non-Metallic Detection | Detects glass, stone, dense plastic, bone | Cannot detect these materials |

| Contaminant Orientation | Less affected by shape/orientation | Highly affected by shape/orientation |

Did You Know? Advanced dual-energy X-ray systems offer superior sensitivity. They can more easily detect difficult contaminants like flat glass and low-density plastics, with some systems identifying hard plastics as small as 2mm.

A modern cheese x ray machine does more than just find foreign objects. It serves as an all-in-one quality assurance station on the production line. By analyzing the X-ray image, the system can perform numerous simultaneous checks to ensure every package meets specifications. This capability helps manufacturers reduce product giveaway and boost profit margins.

Key quality control functions include:

Mass Measurement: The system verifies the weight of the final product and can even measure individual compartments within a package, rejecting any that are over or under the target weight.

Component Counting: It ensures multi-part products, like cheese and cracker packs, contain all the required items.

Fill Level Verification: It checks that containers like yogurt cups or milk cartons are filled to the correct level, providing real-time feedback to filling equipment for automatic adjustments.

Void Detection: For cheese blocks, the system can identify unwanted air pockets or voids that compromise product quality and consistency.

Package Integrity: It inspects package seals for trapped food particles and identifies damaged or deformed packaging that could lead to spoilage.

Implementing advanced inspection technology is a direct investment in brand protection. A single product recall can cause irreparable damage to a company's reputation and financial standing. X-ray inspection provides a reliable, non-invasive solution that safeguards against costly recalls and consumer complaints. One leading dairy company, for example, saw a 30% reduction in customer complaints within six months of implementing an advanced X-ray system.

A robust inspection program serves as a Critical Control Point (CCP) within a Hazard Analysis and Critical Control Points (HACCP) plan. It is the final checkpoint to prevent physical hazards from reaching the consumer.

Using a cheese x ray machine also helps manufacturers demonstrate due diligence and comply with global food safety standards. The technology is recognized by all Global Food Safety Initiative (GFSI) benchmarked schemes and helps meet requirements for:

HACCP

FDA Food Safety Modernization Act (FSMA)

BRC Global Standards

IFS Food

Advanced systems store inspection data and images, providing an auditable trail that proves every product was properly inspected. This documentation is invaluable during audits and demonstrates a clear commitment to producing safe, high-quality dairy products.

Physical contaminants present a serious threat in dairy manufacturing. Understanding sources, from equipment wear to raw materials, is the first step toward mitigation. Implementing a robust Hazard Analysis and Critical Control Points (HACCP) plan and using advanced detection methods like X-ray inspection are critical to safeguard consumer health and protect brand integrity.

Yes. Food X-ray systems use very low radiation levels. The process is completely safe. It does not affect the food's taste, texture, or nutritional value.

X-ray systems detect contaminants based on density. They may miss low-density items like hair or cardboard. Multiple safety methods provide the most comprehensive protection.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Uneven and overlapped product detection, thin & lo...

UHD X-Ray detector, AI large model, all food indus...

Both fat analysis and contaminant inspection (bone...

High cost performance, compact design, high sensit...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

As pet owners increasingly view their companions a...

MoreIn the fast-paced world of food production, ensuri...

MoreAdvanced nut sorting machine technology combines H...

MoreOptical sorting technology has become indispensabl...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis cheese X-ray machine has revolutionized our quality assurance process. The detection of foreign objects and internal voids is incredibly precise, significantly reducing product waste and ensuring consumer safety. The software interface is intuitive.

Sarah Chen

Dairy Production SupervisorA reliable and robust machine for daily inline inspection. It has greatly improved our efficiency in detecting density variations in our aged cheddar blocks. The maintenance is straightforward, and the support team is responsive. Minor learning curve for new operators.

David Miller

Plant EngineerOutstanding investment. The machine's high-resolution imaging allows us to non-destructively analyze cheese structure and maturation consistency. It's built for industrial environments and has drastically cut down our manual sampling time. Integration with our existing line was seamless.

Jessica Williams

Research & Development SpecialistAn indispensable tool in our R&D lab. The detailed internal visualization helps us perfect new cheese formulations and processing techniques. The ability to track structural changes over time is invaluable for product development. Highly accurate and consistent results.