Why X-Ray Inspection for Canned Food is a Non-Negotiable

From sweet corn and peas to green beans and vegeta...

More

Selecting the ideal X-ray system is a nuanced process, not a search for a single top brand. The market's projected 7.39% CAGR underscores the growing need for effective solutions against foreign contaminants. Metal, in particular, remains a primary culprit in recalls.

| Country | Percentage of Physical Recalls Caused by Metal |

|---|---|

| Germany | 52% |

| UK | 45% |

| USA | 36% |

A manufacturer's quest for the best x ray inspection system foir food requires a direct comparison of four core criteria: Detection Sensitivity, Software & Usability, Reliability & Support, and the Total Cost of Ownership. Finding the best x ray inspection system for food is the outcome of this careful evaluation.

Detection sensitivity is the cornerstone of any effective X-ray inspection program. It defines the smallest contaminant a system can reliably identify within a specific product. This capability is not universal; it varies significantly based on the X-ray generator, detector technology, and the software algorithms processing the image. A system excelling with one product type may not be the optimal choice for another.

Mettler-Toledo systems demonstrate high precision, particularly when inspecting dense products where contaminants can be difficult to isolate. The company's Safeline X-ray system utilizes advanced detector technology with a 0.4-mm high-sensitivity detector. This innovation significantly improves detection levels. It maintains consistent sensitivity even with multi-textured foods or products that shift inside their packaging, ensuring reliable performance across various applications.

💡 Pro Tip: This level of precision is critical for products like dense cheese blocks, poultry, and meat, where small bone fragments or metal shavings pose a significant risk.

Eagle PI specializes in advanced imaging for challenging inspection scenarios. Its Material Discrimination X-ray (MDX) technology is a key differentiator. This dual-energy system analyzes a material's chemical composition, not just its density. This allows it to find contaminants in products with high texture and density variations, such as bags of trail mix or mixed salads. MDX technology effectively detects foreign bodies like flat glass, stone, plastic, and rubber compounds that traditional systems might miss.

Eagle PI systems also perform exceptionally well with complex packaging.

They reliably inspect products in challenging containers like metalized pouches or foil trays.

PXT™ detector technologies enhance inspection for superior quality assurance.

The MDX technology improves contaminant detection in these difficult product applications by differentiating between organic product and inorganic contaminants.

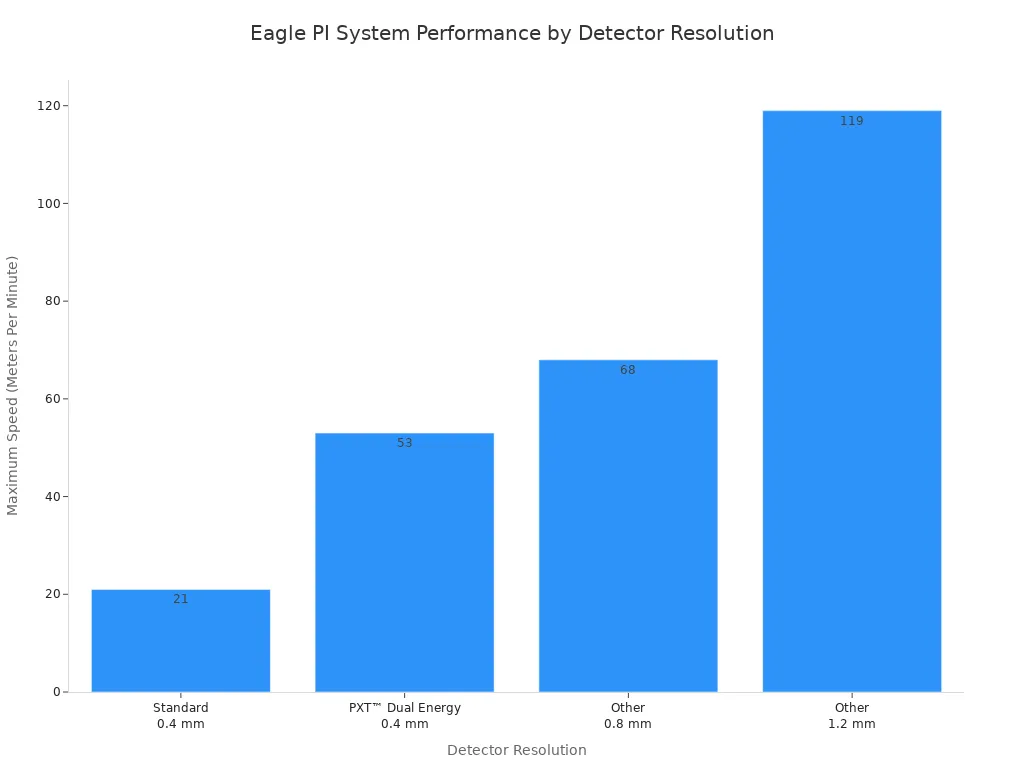

The system's performance is also tied to its detector resolution and line speed, as shown below.

Anritsu systems are engineered to maintain exceptional sensitivity without sacrificing production speed. The XR76 Series X-ray Inspection Systems operate effectively at conveyor speeds between 61 and 90 meters per minute. They achieve this through faster sensor scanning, which produces clear, undistorted images even on high-speed lines. A newly developed high-performance X-ray sensor enhances this capability, improving resolution by up to 40%. This allows for high-precision detection of minute metal contaminants and low-density foreign objects, making it a strong contender for the best x ray inspection system for food in high-throughput facilities.

Loma Systems offers robust and reliable detection for a wide range of general food applications. The X5 series is a versatile workhorse, known for its dependable performance in common production environments like bakeries and ready-meal facilities.

Key detection capabilities include:

Excellent detection of ferrous, non-ferrous, and stainless-steel contaminants.

Dependable identification of glass, bone, ceramic, and dense plastics.

Flawless inspection of products in aluminum trays or metallized foil.

Simultaneous quality checks, such as verifying component counts or measuring product volume.

VJ Technologies (VJT) carves out its niche by providing highly customizable X-ray solutions. While other manufacturers offer standardized models, VJT specializes in engineering systems tailored to unique products or inspection challenges. This approach is ideal for manufacturers with unconventional product shapes, sizes, or packaging that do not fit standard machine apertures. A food producer with a novel product or a particularly difficult inspection requirement may find that a custom-built system from VJT provides the most effective and accurate solution.

Beyond detection, the best x ray inspection system for food must offer software that is powerful, easy to use, and supports data management for compliance. A system's operational efficiency and its ability to provide audit-ready documentation depend heavily on its software interface and data collection capabilities.

Mettler-Toledo excels in providing software that simplifies compliance. Their ProdX software automates data collection, which is essential for meeting global food safety standards. This helps manufacturers prove due diligence and adhere to regulations.

It gathers critical data for HACCP and BRC programs.

The system documents Performance Verification Reports (PVRs).

It records shift reports with throughput, rejects, and machine settings.

Eagle PI systems feature powerful software for deep analysis and connectivity. The SimulTask™ PRO software uses advanced image processing for superior clarity. For larger operations, TraceServer software connects multiple systems into a single network.

It consolidates inspection data into a centralized database.

The system enhances product traceability for quality assurance.

Users can query, view, and export data for remote monitoring.

Anritsu designs its software for speed and simplicity. The user interface features intuitive controls and a logical layout. This design allows operators to perform product changeovers quickly and with minimal training, reducing downtime and maintaining high throughput on busy production lines.

Loma Systems emphasizes user proficiency through accessible software and comprehensive training. Their tiered training programs ensure that all personnel can operate the equipment effectively.

| Course | Target Audience | Key Outcome |

|---|---|---|

| Use | Operators | Basic operation and product setup. |

| Comply | QA Personnel | Advanced setup and validation planning. |

| Maintain | Engineers | Full troubleshooting and repair skills. |

VJ Technologies develops flexible software tailored to its custom-built hardware. Since each system is engineered for a specific application, the software is also bespoke. It provides precise control over the unique mechanical and imaging functions of the machine, offering a highly specialized user experience.

A system's reliability is measured by its uptime, durability, and the support available when issues arise. Downtime directly impacts profitability, so robust construction and responsive service are non-negotiable. The quest for the best x ray inspection system for food must prioritize machines that withstand demanding production environments with minimal interruption.

Mettler-Toledo emphasizes build quality and hygienic design to ensure long-term reliability. Their systems feature significant mechanical upgrades for simplified service and maintenance. This focus on smart design enhances both durability and ease of use.

A front-opening design allows easy access for cleaning and service.

Key components like the conveyor belt can be removed without tools.

Systems are available with ingress protection ratings up to IP69 for harsh environments.

Integrated cable management reduces clutter and potential damage points.

Eagle PI builds its systems with a modular design. This approach allows for quicker repairs and component swaps, minimizing downtime. The company backs its hardware with comprehensive 24/7 technical support, providing food manufacturers with peace of mind and immediate assistance when needed.

Anritsu engineers its machines for extreme durability, particularly in facilities with intensive washdown procedures. The XR75 IP69K Sanitary model is built to withstand high-pressure, high-temperature cleaning. Its IP ratings confirm its resilience.

| Component | IP Rating |

|---|---|

| Conveyor | IP69K |

| Other Parts | IP69 |

💡 Note: The IP69K rating means the conveyor is protected against powerful, high-temperature water jets, making it ideal for meat, poultry, and dairy plants.

Loma Systems has a long-standing reputation for building robust and durable equipment. Their X5 series machines are constructed for longevity in demanding, 24/7 food production lines. This focus on solid construction translates to fewer breakdowns and a longer operational lifespan for the equipment.

VJ Technologies provides support that is as customized as its machines. Because each system is uniquely engineered, the service and maintenance plans are tailored to the specific components and software of that build. This ensures that operators receive expert support relevant to their one-of-a-kind inspection solution.

The initial purchase price of an X-ray system is only the tip of the iceberg. A true evaluation requires calculating the Total Cost of Ownership (TCO), a comprehensive assessment of all expenses incurred over the machine's entire lifecycle. Finding the best x ray inspection system for food involves looking beyond the sticker price to understand the long-term financial impact. A full TCO calculation considers installation, training, utilities, maintenance, and potential downtime to reveal the investment's true value.

Key factors in a TCO calculation include:

Running Costs: Annual power consumption, water usage, and the effect of maintenance routines on uptime.

Service Costs and Spare Parts: Preventive maintenance, software updates, and operator training.

Engineering and Design: Hygienic features that reduce sanitation time and improve turnaround.

Life Expectancy: The longevity of core components like the X-ray generator and the overall machine.

Performance and Technology: Accuracy, reliability, and the cost of false rejects or missed contaminants.

Ease of Use: The impact of user-friendly interfaces and simple changeovers on labor hours.

Downtime Risks: Time lost due to part changes, software issues, or the need for technical support.

Mettler-Toledo systems often represent a significant capital expenditure. However, their TCO model focuses on balancing this upfront investment with lower long-term operational costs. The company achieves this through superior engineering and hygienic design. Features like tool-free belt removal and IP69-rated construction drastically reduce the time and labor required for sanitation and maintenance. This efficiency translates directly into lower running costs and increased production uptime, delivering a predictable and favorable TCO over the machine's lifespan.

Eagle PI presents a compelling TCO argument centered on Return on Investment (ROI) from superior performance. The primary value driver is the reduction of false rejects. Advanced technologies like Material Discrimination X-ray (MDX) and PXT™ provide exceptional accuracy, especially with challenging products.

💡 ROI in Action: By minimizing the amount of good product that is incorrectly discarded, Eagle systems reduce product waste and protect profit margins. This "hidden" saving is a critical component of their TCO, often justifying the investment in their advanced technology. The system's ability to perform simultaneous quality checks further enhances its value proposition.

Anritsu positions itself as a provider of high overall value with competitive initial pricing. Their TCO is attractive to manufacturers seeking a balance of performance, durability, and affordability. The robust construction, particularly in their IP69K-rated models, ensures a long life expectancy with minimal service interventions, lowering long-term service costs. Anritsu's focus on high-speed operation without compromising sensitivity means manufacturers can maintain high throughput, maximizing production volume and contributing positively to the overall financial equation. This makes it a strong candidate for the best x ray inspection system for food in budget-conscious, high-efficiency plants.

Loma Systems offers a strong value proposition for standard food production applications. Their TCO is built on a foundation of reasonable upfront costs combined with robust, reliable machinery that ensures a long operational life. For many bakeries, ready-meal facilities, and similar plants, a Loma system provides the necessary detection capabilities without the expense of highly specialized technology.

| Cost Category | Loma Systems TCO Factor |

|---|---|

| Upfront Costs | Competitive hardware and software pricing. |

| Operational Costs | Durable construction leads to a long system lifespan. |

| Hidden Costs | Strong reliability minimizes costly production downtime. |

This balance makes their systems a cost-effective and predictable investment for a wide range of general inspection needs.

The Total Cost of Ownership for a VJ Technologies system is fundamentally different because it is based entirely on the level of customization. There are no standard models; each machine is engineered to solve a unique inspection challenge. The initial cost directly reflects the complexity of the engineering, hardware, and software required. While the upfront investment can be substantial, the ROI is measured by the system's ability to perform a task that no standard machine can. The TCO includes tailored service plans and support, ensuring the specialized equipment remains operational. For a manufacturer with a niche product, the value lies in enabling market access and ensuring safety, a return that far outweighs the bespoke cost.

A manufacturer's evaluation of product, production, and business goals determines the ideal system. This guide helps create a matrix comparing brands against the four core criteria. After installation, tracking key performance indicators (KPIs) measures value:

Operational: Equipment utilization rate

Quality: Error or repeat exam rate

Financial: Cost per exam

This comprehensive approach ensures selection of the best x ray inspection system for food.

Yes. Food passes through the beam too quickly to be harmed. The radiation levels are extremely low. The FDA confirms X-ray inspection does not make food radioactive.

Metal detectors only find metallic contaminants. X-ray systems detect a wider range of foreign bodies, including glass, stone, and bone, while also performing simultaneous quality checks.

No. X-ray inspection performance remains consistent across frozen, chilled, and ambient temperature products. This makes it a versatile solution for various production lines and product types.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

High cost performance, compact design, high sensit...

Recommedation: Frozen vegetables such as green be...

Uneven and overlapped product detection, thin & lo...

Automatic recognition and rejection, fish bone ins...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

From sweet corn and peas to green beans and vegeta...

MoreOptical sorting technology has become indispensabl...

MoreCupped products, such as Greek yogurt and multi-co...

MoreRaymanTech, as a leading provider of inspection an...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis X-ray inspection system has revolutionized our food safety protocols. The detection accuracy for contaminants like metal fragments and glass shards is exceptional. Our production line efficiency improved by 30% while maintaining perfect safety standards.

Sarah Chen

Production SupervisorAfter testing multiple systems, this X-ray inspection unit stands out for its remarkable sensitivity and user-friendly interface. It reliably detects even the smallest foreign objects in our packaged snacks without slowing down our production speed.

David Thompson

Food Safety DirectorThe advanced imaging technology and AI-powered analysis make this the best X-ray inspection system we've ever used. It consistently identifies contaminants in our meat products that other systems might miss, giving us complete peace of mind.

Jennifer Wallace

Operations ManagerThis system's ability to inspect sealed containers and detect density variations is outstanding. It has significantly reduced our product recall risks and enhanced our quality assurance processes across all our dairy product lines.