Bakery X-ray Inspection Systems: AI Solutions for Bread & Pastry Safety

Bakery X-ray Inspection Systems have emerged as the standard for modern quality control. Unlike magnetic detection, X-ray technology allows bakers to "see" through density, ensuring safety from the core of a frozen dough ball to the seal of a flow-wrapped croissant.

Whether you are producing artisan loaves or mass-market cookies, this article explores how X-ray inspection for bread and bakery products safeguards your production line using the latest AI-driven technology.

Why Switch to X-ray Technology for Bakery Inspection?

While metal detectors are effective for conductive metals, modern bakery processing faces contamination risks that magnetic fields cannot catch. Ingredients like stone (from flour milling), glass (from broken jars), and calcified bone are common hazards.

X-ray Technology Bakery Inspection offers distinct advantages:

● Overcoming the "Product Effect": Hot, fresh bread often has high moisture and salt content, which creates a "product effect" that triggers false rejects in metal detectors. X-ray systems are unaffected by temperature, moisture, or salt.

● Non-Metallic Detection: It easily identifies high-density plastic, rubber, stone, and glass.

● Packaging Flexibility: It is the only solution for inspecting products packaged in metallized film or aluminum foil trays.

Applications: Precise Defect Detection by Category

Based on industry-specific processing data, X-ray systems provide tailored inspection capabilities for every stage of bakery production. Here is how advanced systems handle specific categories:

1. Bread and Rolls

● Products: Commercial Bread (white, whole wheat), Dinner Rolls, and Sandwich Buns.

● Contaminant Control: Detects metal (from repair welding slag or drilling debris), stone, and glass.

● Quality Assurance:

○ Packaging Integrity: Verifies the correct amount of filling in stuffed rolls.

○ Missing Components: Checks for essential inserts like deoxidizers, desiccants, manuals, or dividers.

2. Pastries and Croissants

● Products: Danish Pastries, Sweet Rolls.

● Key Inspections: Beyond contaminants, X-ray systems ensure the correct amount of filling, which is critical for product consistency. They also verify the presence of promotional gifts or inserts inside the packaging.

3. Cookies and Biscuits

● Products: Chocolate Chip Cookies, Oatmeal Cookies, Crackers.

● Defect Detection: X-ray is vital for aesthetic quality control. It detects damages, breaks, cracks, or under-formed shapes before they reach the customer.

● Safety: Automatically rejects packs with missing deoxidizers or dividers.

4. Cakes and Cupcakes

● Products: Pre-Packaged Layer Cakes and Sheet Cakes.

● Complex Assemblies: These products often contain accessories. The system verifies the inclusion of knives, dishes, garnishes, and manuals, ensuring the consumer gets the full package.

5. Muffins and Scones

● Products: Fruit Muffins, Bran Muffins.

● Specialized Checks:

○ Seal Clip Verification: Checks if the Seal Clip Material is present and correctly applied.

○ Filling Levels: Monitors the density of fruit or cream distribution.

6. Frozen and Specialty Products

● Products: Frozen Pizza Crusts, Flatbreads, Bagels, and Frozen Pies.

● The Frozen Advantage: Frozen dough is dense and hard, making physical probing impossible. X-ray beams penetrate easily to find contaminants like welding slag or stone and perform a final count check for inserts and dividers.

RaymanTech Solutions: The Future of Bakery Inspection

To address these diverse challenges, industry innovators like RaymanTech utilize "Whole Chain" inspection strategies combined with Artificial Intelligence.

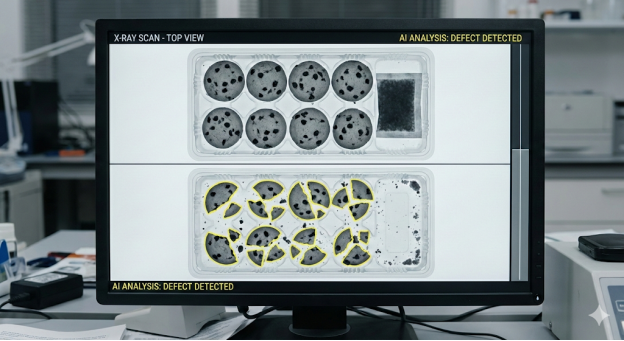

AI-Powered X-Ray Inspection for High Accuracy

Standard inspection methods often struggle with the porous nature of baked goods. RaymanTech's AI-Powered systems use deep learning to solve this:

● Intelligent Differentiation: The AI distinguishes between foreign bodies and the natural air pockets or nuts in muffins.

● Reduced Waste: Drastically lowers false reject rates caused by product texture variations.

Compact Economical Food X-Ray Inspection Systems

Space is often limited in bakeries. Compact Economical models provide a solution that fits into tight production lines without sacrificing power.

● Plug-and-Play: Designed for easy integration and immediate use.

● Cost-Effective: Makes high-end x ray inspection for bread accessible to small and medium-sized producers.

Whole Chain Inspection Solution

RaymanTech advocates for a holistic approach:

1. Raw Material: Scanning bulk flour and sugar.

2. Processing: Inspecting dough and batter prior to baking.

3. After-Package: Final verification of sealed boxes and bags.

Frequently Asked Questions (FAQs)

Q1: Can X-ray inspection detect plastic contaminants in bread?

A: It depends on density. High-density plastics (like rigid conveyor pieces) are detectable. While thin plastics like film are challenging, modern AI-powered systems are significantly improving detection rates for these lower-density materials compared to traditional machines.

Q2: Will X-ray inspection affect the taste or safety of bakery products?

A: No. The X-ray energy used is extremely low and strictly regulated. It does not make the food radioactive, nor does it alter the texture, taste, or nutritional value of the bread or pastry.

Q3: How does X-ray technology handle the air bubbles in bread?

A: This is a common concern. Advanced algorithms allow the system to "learn" the product's structure. The software ignores the natural air voids (density changes) in bread while still flagging denser contaminants like metal or glass.

Q4: What happens if a deoxidizer packet is missing?

A: The system performs a "Missing Component" check. By analyzing the density image of the final package, it can confirm if the deoxidizer (or other items like plastic knives) is present. If it's missing, the product is automatically rejected from the line.

Q5: Is X-ray inspection suitable for frozen dough?

A: Yes, it is ideal. Frozen products are consistent in density, which actually makes X-ray inspection highly effective. It can easily detect contaminants inside the frozen block that would otherwise be invisible.

Related Articles

-

Dec-19-2025

Optical, X-Ray, and AI Solutions of Bean Sorting

Whether you are processing Kidney Beans, Black Beans, or high-value Chickpeas, modern bean sorting machines are the gatekeepers of food safety. This guide explores the cutting-edge technologies—from standard optical sorting to AI-driven deep learning and X-ray inspection—that ensure your product meets the highest global standards.learn more -

Dec-19-2025

Dec-19-2025Comprehensive Introduction to IP69K Protection Rating — The Gold Standard for Equipment in Meat and Food Processing Environments

Why do IP65/IP67 fail in food plants? Discover the engineering behind true IP69K hygienic design and our water-resistant X-ray inspection solutions.learn more -

Dec-19-2025

Dec-19-2025Peanuts Optical and X-Ray Sorting Technologies

For processors, the challenge is evolving. It is no longer enough to just remove stones or discolored nuts. The modern production line must detect invisible threats—from internal mold (a precursor to Aflatoxin) to low-density contaminants like plastic ties. This guide explores how integrating peanut optical sorting and X-ray inspection creates a "zero-defect" defense system.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057