The Essential Role of Raisins Optical Sorting Machines

Raisins present a unique set of challenges: they are naturally sticky, vary significantly in moisture content, and often arrive from the vineyard mixed with difficult-to-detect debris. As a cornerstone of the modern production line, a high-quality dried fruit sorting machine does more than just separate good fruit from bad; it protects brand reputation and ensures strict food safety compliance. Whether you are processing sun-dried Thompson Seedless or delicate Golden raisins, implementing an intelligent sorting solution is essential for operational efficiency.

Overcoming the Challenges of Raisin Inspection

Traditional mechanical sorting can remove large debris, but it often fails to detect subtle defects or foreign materials that mimic the product's density or color. RaymanTech's Raisins Optical inspection system leverages Artificial Intelligence (AI) and Ultra-High-Definition (UHD) imaging to identify contaminants that the human eye might miss.

This technology is particularly vital for handling the distinct requirements of different raisin varieties.

Tailored Inspection Strategies: Standard vs. Golden Raisins

To achieve the highest market standards, sorting equipment must be versatile enough to switch between different inspection priorities. The table below outlines the key differences in processing these two common varieties:

Feature | Standard Dark Raisins | Golden Raisins |

Primary Goal | Purity & Foreign Material Removal | Color Consistency & Visual Appeal |

Key Contaminants | Stones, twigs, dirt, glass | Green/unripe berries, discolorations |

Critical Defect | Damaged or cap-stemmed fruit | Variation in color hue |

Technology | Shape & Foreign Object Detection | Advanced Color & Spectrum Analysis |

Following this strategic approach, modern optical sorters utilize specific algorithms to handle these differences:

· Standard Raisins: Processing dark raisins requires a keen eye for physical contaminants. The optical sorting machine checks the size, shape, and color uniformity of raisins, removing damaged, overripe, or discolored raisins, and detecting and removing foreign objects such as stones, twigs, and dirt. This ensures that the final pack contains only plump, uniform fruit, free from the field debris that often accompanies the harvest.

· Golden Raisins: Visual appeal is the primary selling point for this variety. For golden raisins, optical sorting ensures consistent color and removes any green or unripe raisins that could affect the product's visual appeal and taste. By strictly controlling the color spectrum, processors can guarantee a vibrant, premium product that commands a higher price point.

Technology Spotlight: RaymanTech AI Sorting Solutions

Based on industry innovations, specifically those found in RaymanTech's AI Medium Speed Optical Sorter, modern machines are built to tackle the specific pain points of raisins sorting:

1. Handling Sticky and Fragile Products:

Raisins are notoriously sticky and prone to skin damage. While traditional chute sorters can cause blockage or breakage, RaymanTech recommends Belt Optical Sorters (such as the ROS-600DBLS model). The horizontal belt mechanism ensures smooth transport at speeds up to 96m/min, minimizing damage to the fragile skin of the dried fruit while preventing agglomeration.

2. AI Deep Learning & UHD Imaging:

Equipped with 1024x1024 or 2048x2048 pixel cameras, these systems can detect minute impurities. The AI algorithms are trained to identify specific organic contaminants like stems (cap stems), mold, and insect damage, as well as non-organic items like glass or plastic.

3. Hygiene and Durability (IP Rating):

Dried fruit processing environments can be dusty or require frequent washdowns. RaymanTech systems feature IP65 protection, ensuring the machine operates reliably in wet and high-dust environments. The quick-release belt mechanism further simplifies the cleaning process, significantly reducing downtime.

The Benefits of Automating Raisin Inspection

Investing in a robust Raisins Optical inspection system provides immediate ROI through:

· Labor Replacement: High-speed sorting drastically reduces the need for manual inspection, cutting labor costs and eliminating human error.

· Yield Maximization: Intelligent rejection systems utilize precise air jets to remove only the defect, keeping good product in the stream and minimizing waste.

·Food Safety Compliance: With the ability to detect metal, glass, and stones, processors can confidently meet strict international food safety standards.

Conclusion

The future of raisin processing lies in intelligent integration. From removing field debris in Standard Raisins to perfecting the hue of Golden Raisins, optical sorting technology is the gatekeeper of quality. By leveraging RaymanTech's advanced sorting solutions, processors can ensure every pack leaving their facility is safe, uniform, and high-quality.

Ready to upgrade your processing line? Contact RaymanTech(https://www.raymantech.us/contact/) today to request a quote or a demo of our industry-leading sorting solutions.

Frequently Asked Questions (FAQs)

Q1: Why are belt sorters preferred over chute sorters for raisins?

A: Raisins are often sticky or sugared. Chute sorters can suffer from material blockage due to this stickiness. Belt Optical Sorters, like RaymanTech's AI Medium Speed series, transport the product stably without clogging and are gentler on fragile skins, preventing breakage.

Q2: Can the machine detect foreign materials that look like raisins?

A: Yes. Advanced Raisins Optical inspection systems combine visible light cameras with AI algorithms. This allows the machine to distinguish materials based on shape, texture, and density, removing dark stones or glass that might visually blend in with dark raisins.

Q3: How difficult is it to clean the machine between product changeovers?

A: It is designed for efficiency. RaymanTech machines feature a quick-release belt mechanism and a waterproof design (IP65), making them easy to wash down and sanitize quickly between batches to prevent cross-contamination.

Q4: Does the system detect micro-impurities?

A: Yes, modern AI optical sorters are capable of detecting very small impurities, including hair, fine strings, and insect fragments, ensuring a high level of hygiene for the final product.

Related Articles

-

Nov-26-2025

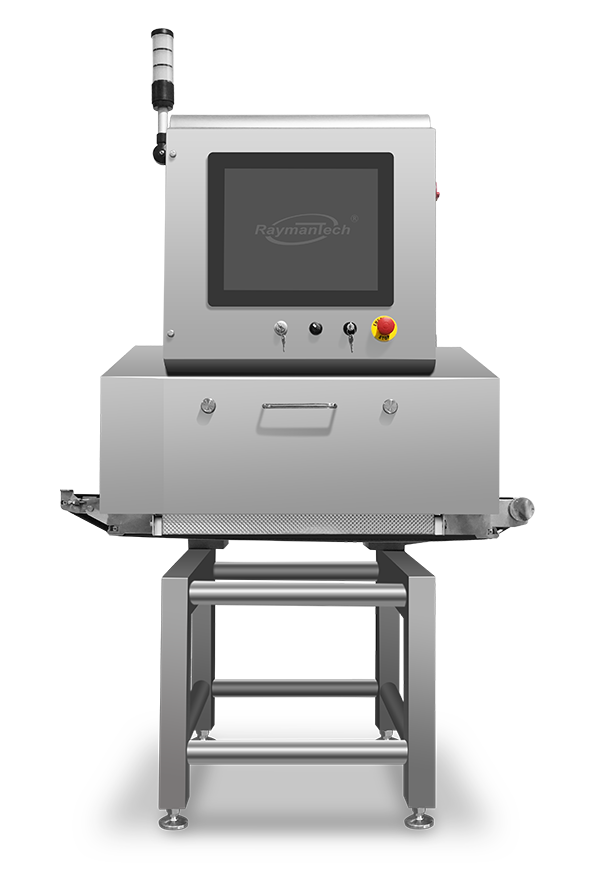

Nov-26-2025RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.learn more -

Nov-26-2025

Nov-26-2025Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.learn more -

Nov-26-2025

Nov-26-2025How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about contamination in food – broken glass, metal fragments, plastic or stone – entering a product and harming someone or prompting a recall. X-ray inspection systems have become a key solution: conveyors carrying packaged or unpackaged food pass through a shielded X-ray machine that “sees” inside each item. This technology complements traditional metal detectors and manual checks to catch a wider range of hazards. Importantly, extensive research and industry experience show that food X-ray inspection is extremely safe. Nearly everything we eat – from spices to snacks – is X-rayed at some point during production, and regulatory bodies (like the FDA) report “no known adverse effects” from the low-dose X-ray scans used in food plants.learn more -

Nov-26-2025

Nov-26-2025The Ultimate Guide to Lamb X-Ray Inspection

Lamb and mutton products hold a premium spot in the global meat market, prized for their flavor and nutritional value. However, ensuring these products reach the consumer free from contaminants is a complex challenge facing processors today. From tiny bone fragments hidden in ground meat to broken needles left behind from vaccinations, the risks are real.learn more -

Nov-26-2025

Nov-26-2025Why X-Ray is Superior for Chocolate Inspection

For manufacturers, ensuring that every bite is safe and perfect is not just a goal—it is a necessity. This is where x ray chocolate bars inspection technology becomes a critical asset. Here is a comprehensive guide to how X-ray inspection secures quality for both solid and filled chocolate products, powered by RaymanTech’s intelligent solutions.learn more -

_1.png) Nov-26-2025

Nov-26-2025Corn Sorting Solution for Modern Processing

In the competitive global grain market, consistency and purity are the currencies of trust. From raw harvesting to final packaging, ensuring that every kernel meets the highest standards is a challenge that manual labor can no longer sustain. This is where advanced corn optical inspection systems step in—transforming how yellow corn, white corn, and popcorn are processed, graded, and valued.learn more -

Nov-26-2025

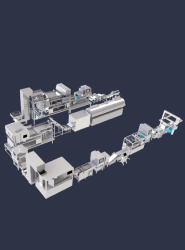

Nov-26-2025RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolved dramatically. Modern food processors can no longer rely on spot-checks or isolated inspection points — contaminants, defects, and non-conformities can originate at any stage: raw ingredients, processing, or final packaging. RaymanTech’s Whole-Chain Inspection & Sorting Solutionlearn more -

Nov-26-2025

Nov-26-2025X-Ray Inspection of Cheese

Today, advanced X-ray inspection systems have become a critical plan for modern cheese processors. They move beyond simple metal detection to offer a complete quality assurance solution, protecting consumers and preserving brand integrity.learn more -

Nov-26-2025

Nov-26-2025The Critical Role of X-Ray Inspection for Shrimp

For seafood processors, protecting the consumer and the brand is paramount. A single, minuscule foreign object—a fragment of glass, a metal wire, a dense piece of plastic—can lead to consumer injury, a devastating product recall, and irreparable damage to a brand's reputation. Traditional inspection methods, while valuable, often fall short of this modern challenge.learn more -

_1.png) Nov-26-2025

Nov-26-2025Beyond the Basics: A Professional Guide to Almond Sorting Technology

In the almond industry, quality is non-negotiable. Processors face a complex challenge: removing not only obvious foreign matter but also subtle product defects, internal damage, and micro-impurities. A single sorting machine is no longer the answer. Today, success demands an integrated, full-process strategy.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057