Principle of X-ray Inspection Machines in the Food Industry

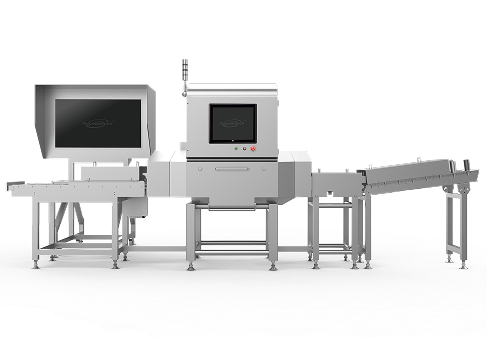

Ensuring food safety is critical: every year, millions of pounds of products are recalled due to foreign contaminants. X-ray inspection machines have become indispensable tools for food producers to catch hazards before products leave the plant. Unlike manual or camera-based checks, an X-ray system "sees" inside packaged or unpackaged items using penetrating radiation. This allows it to detect a wide range of physical contaminants (metal, glass, stone, bone, plastic, etc.) and quality defects (e.g. missing pieces, cracks) that other methods can miss. RaymanTech, for example, offers a Standard X-ray Inspection System that uses high-energy X-rays to find both metallic and non-metallic contaminants. Such systems help manufacturers meet stringent safety standards and protect brand reputation by preventing dangerous products from reaching consumers.

How X-ray Inspection Works

An X-ray inspection machine has three main parts: an X-ray generator, a detector array, and a computer processing unit. First, a high-voltage X-ray tube produces a fan-shaped beam of X-rays. Electrons are accelerated in the tube and strike a metal target, emitting X-ray photons in a directed beam. This beam passes through the food product on a conveyor: as X-rays travel through the product, denser areas (like foreign objects) absorb more radiation than the surrounding food.

The remaining X-rays hit a sensor array (often a line of photo-diodes), which measures the intensity of X-rays that exit the product. This converts the pattern of transmitted X-rays into electrical signals and ultimately a grayscale image. In that image, ordinary product appears in uniform gray, while a contaminant (being denser) appears as a darker shadow. A high-speed computer then analyzes each image pixel-by-pixel against thresholds to flag any anomalies. In practice, if an X-ray image shows an unexpected dark region, the system rejects that package or triggers an alarm.

Key points of this process include:

Density-based detection:

X-rays lose energy as they pass through material. A piece of metal, glass or stone absorbs more X-rays than the food itself, creating contrast in the image. This density difference is the basis for detection.

Shielding and safety:

Modern food X-ray systems use shielding enclosures and high-voltage tubes (not radioactive isotopes). When the machine is off or idle, it emits no radiation. Emissions during operation are extremely low – typically well below natural background levels. Regulators (FDA in the US, and others internationally) set strict safety standards for these machines, including interlocks and warning lights, so operator exposure is negligible.

Imaging and rejection:

Each unit on the line is scanned in milliseconds. The software compares the live image to reference "good" images and automatically rejects any item with a detected foreign object or defect. Advanced systems can even log X-ray images and product data for traceability.

In summary, X-ray inspection translates the principle of differential absorption into a practical detection tool. When an X-ray passes through a product, it gradually loses energy. Areas of higher density, like contaminants, absorb more energy, resulting in an even greater reduction. This energy is then converted by a sensor into a grayscale image. The computer analyzes this image to detect variations in shade—specifically, darker areas that indicate potential contaminants within the product. RaymanTech's machines follow the same approach, using high-resolution detectors and image analysis to flag anything unusual in the food.

Comparing X-ray to Other Inspection Technologies

Metal Detectors

Metal detectors remain a first line of defense in food processing. They are highly effective at finding ferrous, non-ferrous (e.g. aluminum, copper) and stainless steel contaminants. These systems use electromagnetic coils: when a metal particle passes through, it disturbs the radio-frequency field and triggers an alert. RaymanTech also offers a range of metal detectors (often built into conveyor frames) that excel at this task. For example, RaymanTech's Conveyor Belt Metal Detector can be tuned to reject tiny metal fragments from both packaged and bulk products.

Pros of metal detectors: They are generally inexpensive, have long lifespans, and can be finely tuned for different metals (some even use multiple frequencies to detect small stainless steel shards). Metal detectors are also very fast and require minimal training to operate.

Cons: Metal detectors can only see metal. They completely miss non-metal hazards. If a food product is contaminated with glass, stone, bone, rubber or hard plastic, a metal detector won't catch it. They are also sensitive to the "product effect" – items with high moisture, salt or minerals can produce false signals. Moreover, metal detectors cannot inspect through metalized packaging or foil pouches; a metal detector would be blinded by the package itself.

By contrast, X-ray systems inspect the entire product content regardless of packaging. As our previous blog notes, X-ray inspection is widely used in the food industry because it can detect a broad range of contaminants, both metallic and non-metallic — such as metal, glass, plastic, stone, and bone. This means X-ray scanners can see a glass shard inside a sealed bag of chips or a bone fragment in a chicken nugget – situations where a metal detector would fail.

Visual Inspection

Another common method is human or camera-based visual inspection. Workers or machines inspect products for visible defects or foreign objects. However, human vision is slow and error-prone, especially with large volumes. Automated cameras can check for size, color or label defects, but they only see the surface of a product. Neither humans nor optical systems can see inside packaging or spot a clear glass fragment in opaque fluid.

X-ray inspection excels where visual inspection fails: it literally "sees" inside the item. A conveyor camera might miss a tiny piece of glass inside a sealed pastry, but an X-ray unit will flag the shadow. Even cameras combined with AI can only detect anomalies within the visible spectrum; X-ray goes beyond, detecting density differences that are invisible externally. RaymanTech even offers advanced systems (X-ray plus AI) for full coverage, but when it comes to hidden contaminants, X-ray is the go-to solution.

Checkweighers and Other Systems

Checkweighers (which verify product weight) and optical sorters (which classify by color/shape) are also used in quality control. However, these systems serve different purposes. A checkweigher ensures packages have the right weight but cannot detect foreign objects. An optical sorter can separate bad from good by color or shape differences, yet it won't spot a clear contamination hidden inside. X-ray inspection is complementary: it can work alongside checkweighers to ensure both correct weight and no foreign matter.

In practice, many facilities deploy a combination of these technologies. For example, one might use a metal detector early in the line for raw bulk ingredients, then an X-ray scanner at final packaging to catch anything that slipped through. So we advice that metal detectors and X-ray inspection often beneficial to employ both to guarantee final product integrity.

Benefits of X-ray Inspection Systems

Food manufacturers adopt X-ray inspection machines for many reasons. Key benefits include:

Broad Spectrum Detection:

X-ray systems catch both metal and non-metal hazards. They can find glass shards, stones, dense plastic pieces, ceramic fragments, and even bone. This dramatically reduces the chance of a foreign object recall. RaymanTech's MULTI BEAM SERIES X-Ray Inspector, for instance, is designed to detect "broken glass, metal shavings, thin plastic, sand, and other impurities".

Packaging Independence:

X-rays penetrate most packaging. Even if a food item is in a foil pouch or metalized film, the scanner can image inside. X-ray systems can "see through" all types of packaging to inspect the contents. This is especially valuable for products that cannot be metal-detected (like juices in foil or ready meals in trays).

Quality Control Tasks:

Modern X-ray units often do more than foreign-body detection. Many have built-in software to check product integrity: they can measure fill levels, verify part counts, detect missing pieces, check seal integrity, and even measure mass or density. For example, an X-ray system could confirm that a multi-compartment pack contains all its components and that each is filled correctly. By combining multiple inspection jobs in one machine, companies can reduce the number of separate devices on the line.

Speed and Throughput:

Despite their complexity, X-ray machines are built for high-speed lines. Advanced systems meet modern throughput targets without slowing production. They use high-power X-ray tubes and fast electronics to scan thousands of items per hour. (Of course, a higher scan rate may require tuning sensitivity, but top models balance speed and resolution for real-time inspection.)

Safety and Compliance:

X-ray inspection can help companies comply with stringent food safety standards. Catching contaminants early avoids legal issues and costly recalls. It also protects brand reputation – a single recall can cost millions and undermine consumer trust. As our industry guide warns, "Small incidents can cost millions of dollars, disrupt business, and be damaging to your company's brand," so investing in X-ray (alongside metal detection) is a key preventive measure.

Minimal Product Effect:

Unlike metal detection, X-ray inspection is largely unaffected by product characteristics. Foods with high moisture, salt, or fat (which can confound metal detectors) do not prevent X-ray systems from working effectively. X-ray signals are stable across temperature, humidity, and salt content. It will correctly image a hot canned soup as well as a frozen snack.

Data and Traceability:

Most X-ray machines include data logging. Images of every scanned pack can be saved for auditing, and rejection counts can be recorded. This helps with compliance (e.g. HACCP documentation) and continuous improvement efforts.

In summary, an X-ray inspection system provides a comprehensive layer of safety. It finds hazards beyond the reach of metal detectors or the human eye, supports multiple QC checks in-line, and helps ensure that only flawless products are shipped. X-ray has become an indispensable tool for industries where consumable purity and quality are paramount.

Common Questions from the Food Industry

What contaminants can X-ray systems detect?

X-ray machines can find all metal types and many non-metal hazards. Typical target objects include metal fragments, glass shards, stones, dense plastics, rubber bits, bones, ceramics, insects, and even high-density bones or shells. In other words, anything significantly denser than the product will show up. RaymanTech's literature explicitly lists contaminants like metal, glass, ceramic, stone, bone, hard rubber, and hard plastic as detectable. In contrast, a standard metal detector would only see metal (iron, steel, aluminum, etc.).

Can X-ray damage the food or packaging?

No. The energy used by X-ray inspection is very low compared to any process that could alter food. The exposure time per item is a fraction of a second, and the dose is minuscule. Our Previous Studie shows that X-raying food at typical inspection levels does not make it radioactive or change its nutritional quality. For instance, one analysis notes that the radiation dose to food is around 0.2 millisievert, far below levels that cause any effect. The FDA concurs, stating there are no known adverse effects from eating X-rayed food. Packaging also remains unaffected; the X-ray energy passes through materials without causing chemical change. On the contrary, X-rays can see through opaque or metalized packaging (like foil pouches) to inspect the contents.

How does packaging affect X-ray inspection?

Most packaging is transparent to X-rays. Plastics, glass, paper, and even thin metal foils allow X-rays to pass with only minor attenuation. This is why X-ray units can inspect products in metalized bags or aluminum cans (very useful for high-barrier packaging). Of course, very thick or heavy packaging (like thick metal walls) might block the beam, but for standard food packaging X-ray works fine. This is a key advantage: you do not need to open packages to inspect them.

How is maintenance handled?

Maintenance for X-ray equipment includes routine cleaning and scheduled calibration. For packaged products, the conveyor belt (and any infeed chutes) should be cleaned weekly to remove any residue. For bulk products, the belt should be cleaned daily to eliminate food debris, crumbs, or spilled liquids. Any buildup can cast shadows on the X-ray image and cause false alarms. Operators should inspect and clean the belt, the X-ray window, and reject mechanisms. Every month or quarter, check for wear (e.g. frayed belt edges, cracked covers) and replace parts as needed.

Calibration is typically done on a fixed schedule or whenever product specs change. This involves running known "test samples" or using calibration tools to ensure the system's sensitivity is set correctly. Calibrating maintains accuracy and minimizes false rejects. In summary, basic upkeep (cleaning, mechanical checks) is weekly or daily, and more technical calibration is maybe annual or as recommended by the manufacturer.

Conclusion

In today's food industry, X-ray inspection machines are a key technology for quality assurance. They extend beyond what traditional metal detectors or visual inspection can do, by revealing hidden contaminants and ensuring product integrity without slowing the line. An X-ray system complements other methods: for example, pairing a RaymanTech metal detector (for raw materials) with a RaymanTech X-ray unit on the final line can provide near-total coverage. Manufacturers using these systems achieve high throughput while maintaining the highest safety standards.

RaymanTech's models like the TOP DOWN SERIES for Packaged foods (bags, boxes, cans) and RXI BHD SERIES for bulk products (grains, nuts, beans, cheese, etc.)

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057